Formulating Medicinal, Herbal, and Food Products via Spray Drying

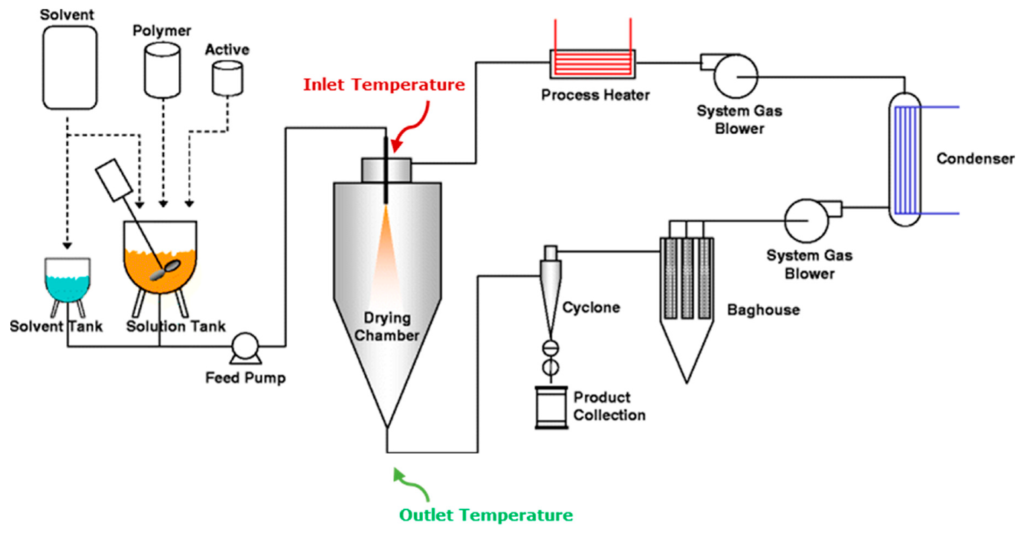

Spray drying is the mechanism of processing fluid into dry matter by spraying the fluid into a hot dry medium particularly as hot gas. The line of action comes into play as an atomizer breaks down the fluid into droplets of the right size and disperses them into the drying medium. The dispersed droplets mix with the hot dry gas. In the drying chamber, an air disperser disperses hot gas. The droplets dry up in a matter of seconds. The powder is collected and separated. The powder is separated in the drying chambers by cone bottoms. A side exit allows the air to escape. High-efficiency cyclones and cloth filters are used to achieve finer separation.

Spray Drying Technology in Pharmaceutical Industry

Spray drying is one of the most impressive pharmaceutical technologies now in use. It is a continuous process that turns a liquid feed into a powder in a single step, and it is an excellent choice when exact characteristics such as particle size, morphology, and stability are required.

Bullock and colleagues pioneered the use of spray drying in pharmaceuticals in the 1940s, using it to dry infusions, extracts, inorganic medicinal salts, adrenaline, and vitamin C. Many more uses followed, with pharmaceutical excipients and the separation of active compounds that were either thermally sensitive or difficult to crystallise being particularly important.

The capacity to obtain powders at the milligramme or gramme scale using lab scale equipment that resembles commercial scale spray dryers is a recent advancement in pharmaceutical spray drying. Traditional lab scale systems used two-fluid nozzles to produce very fine sprays that could be dried in milliseconds due to the limited capacity of the drying chambers. As a result, the powders produced were less than ideal, and they differed significantly from powders produced with larger-scale equipment. Laboratorial scale units have recently been developed using ultrasonic atomisation systems and nearly laminar drying gas profiles, allowing the formation of droplets and, as a result, particles of similar size to those produced by commercial scale units. This capability eliminates or greatly decreases the danger of changing powder qualities during the scale-up and industrialization of the process.

Fig.1. Spray Drying for the Preparation of Dry Powders (MDPI.com)

Spray Drying in Herbal and Food Products

This procedure has dried a variety of biological and thermally sensitive materials, as well as liquid materials such as milk, fruit juices and pulps, herbal extracts, enzymes, essential oils, fragrances, and numerous medications. Its ability to handle thermally sensitive materials is largely owing to the product’s brief resident time inside the dryer.

Consumers are increasingly interested about the health advantages linked to phytochemicals found in so-called functional foods and nutraceuticals, particularly herbal dry extracts. Several words with comparable connotations have been used to describe these goods, including “functional foods,” “medical foods,” “dietary supplements,” and “health foods,” although the term nutraceutical is the most commonly used. A nutraceutical is a food or component of a food that has medical-health benefits, such as illness prevention and/or therapy.

Quality Changes During Spray Drying

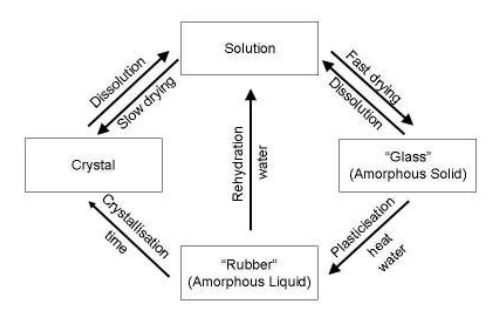

When a liquid material is dried, it undergoes significant physical and chemical changes. Because most foods, herbal extracts, and other biomaterials have a complex composition, these changes are difficult to characterise and can persist during product storage. Drying is a process that transforms a viscoelastic or liquid material into a solid state. The dried substance might be crystalline or amorphous in nature. Amorphous behaviour has been reported in spray-dried materials in the past. Roos postulated a mechanism for the creation of amorphous structures during dehydration, as well as correlations between equilibrium and nonequilibrium states. Glass transition temperatures and environmental variables have been connected to this occurrence.

Fig.2. Formation of amorphous structures in dehydration and the relationships between equilibrium and non-equilibrium.

Drying Aids

Other names for drying aids include drying carriers, drying adjuvants, and wall materials (in microencapsulation). Because of its impact on powder characteristics and product stability, adding drying carriers to the feed solution is critical in the spray drying process. As drying carriers, high molecular weight carbohydrates such as starch and modified starches, maltodextrins, solid corn syrups, gum arabic, and cyclodextrins are commonly utilised. One of the most important tasks of the drying carriers is to raise the product’s glass transition temperature, minimising stickiness and wall deposition during spray drying, as well as its agglomeration propensity during spray drying and storage, resulting in a more stable product.

Spray Drying of Selected Food & Herbal Products

Fruit Pulp: A considerable amount of fruits and vegetables are produced in tropical and subtropical nations, which are particularly appealing from a commercial standpoint. However, there have been modifications in food consumption in recent years. In order to have a balanced and nutritious diet, consumers have been looking for healthier and more natural food product development. Since their nutritional worth as sources of vitamins and minerals has been known, people have been advised to increase their regular diet of fruits and vegetables.

Herbal Extracts and Nutraceuticals: Many phytochemical substances are found in vegetable materials, many of which have been shown to have health-promoting and medicinal characteristics. The food industry preferred the terms functional foods and nutritious foods, as they approached the debate from a nutritional standpoint. Pharmaceutical businesses, on the other hand, favour medical foods, nutraceuticals, and functional foods, and approach the problem from a medicinal standpoint.

Natural Colorants and Colouring Extracts: Due to legislative limits and customer preferences, several vegetal resources have valuable use as a source of natural dyes and colouring extracts aimed at replacing chemical dyes. Natural colourants such as anthocyanins and carotenoids are widely used in food, cosmetics, and animal feed. These compounds are also non-toxic and have good impacts on human health.

Summary

Spray drying is a powerful technical method because it allows for the manufacture of free-flowing particles with precise particle sizes. This is a low-cost manufacturing method that can produce dry particles in the submicron to micron range. In order to manufacture products with desirable attributes, the benefits and downsides of each parameter should be considered. Such characteristics should not be analysed separately, but rather as part of a larger model that adds to the spray-drying process’ performance. This manufacturing process’ scalability and cost-effectiveness in producing dried particles on a submicron-to-micron scale favours a growing number of applications in the food, chemical, polymeric, pharmaceutical, biotechnology, and medical industries.

Reference

- Ricarte, Ralm G.; Van Zee, Nicholas J.; Li, Ziang; Johnson, Lindsay M.; Lodge, Timothy P.; Hillmyer, Marc A. (2019-09-05). “Recent Advances in Understanding the Micro- and Nanoscale Phenomena of Amorphous Solid Dispersions”. Molecular Pharmaceutics.

- Geranpour, M., Assadpour, E., & Jafari, S. M. (2020). Recent advances in the spray drying encapsulation of essential fatty acids and functional oils. Trends in Food Science & Technology.

- Filková, I., & Mujumdar, A. S. (2020). Industrial spray drying systems. In Handbook of industrial drying (pp. 263-307). CRC Press.

- Sarabandi, K., Gharehbeglou, P., & Jafari, S. M. (2020). Spray-drying encapsulation of protein hydrolysates and bioactive peptides: Opportunities and challenges. Drying Technology, 38(5-6), 577-595.+