Microencapsulation in the Food and Beverage Industry

Introduction:

Encapsulation is a physicochemical process where substances, such as bioactive material, are coated in another material, leading to particles ranging from nanometer to a few millimetres. Microencapsulation is an encouraging technique that provides a stable, protective barrier, controlled release and specific target delivery. The targeted release improves the effectiveness of the bioactive compounds, broadening the application and ensuring optimal dosage, thereby improving the cost efficiency for food product development company. Microencapsulation can be achieved by various techniques such as coacervation, emulsification, phase separation, spray drying, chilling, extrusion coating and freeze-drying.

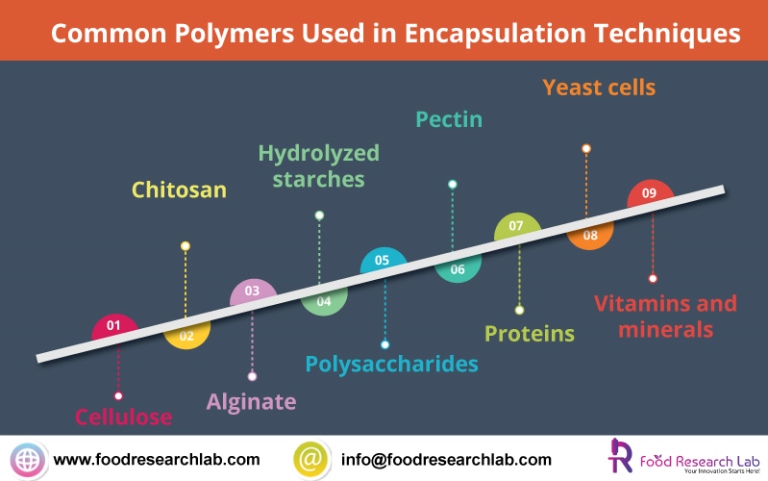

Common polymers used in encapsulation techniques:

Cellulose is a macromolecule composed of glucose, with its main components obtained from the plant cell wall, polysaccharide. To improve the solubility, the hydroxyl groups in cellulose polymers are esterified into derivatives, such as methylcellulose (MC), carboxymethyl cellulose (CMC), and hydroxypropyl cellulose (HPC). Oils tend to get oxidized and produce unpleasant odours and therefore need to be sheltered in microcapsules (1).

Chitosan is one of the widely available biological polysaccharides found in nature. Chitosan is non-toxic, biocompatible and enhances osmotic effects. Chitosan, a cationic polymer, is used in fruit and vegetable, possessing strong antibacterial and antioxidant properties.

Alginate is a natural polysaccharide and which, when combined with various cations, forms different alginate salts. Alginate is commonly used in the development of a controlled-release system, due to its great stability, chelation thickening and film-forming properties. Sodium alginates are cheap and easily form a gel with calcium ions.

Hydrolyzed starches can be obtained by acid or amylase treatment. Dextrose equivalent (DE) was reported to demonstrate a higher degree of starch hydrolysis and aids in browning, viscosity, and oxidative resistance. Maltodextrin and corn syrup are common examples of hydrolyzed starches. Encapsulated olive oil with starch exhibited higher oxidative stability and the best adsorption capacity was found at 45°C and pH 5.0.

Polysaccharides are the preferred shell phase for food encapsulation techniques. Polysaccharides are composed of repeating monosaccharide units connected via glycoside bonds.

Pectin is commonly obtained in the plant cell walls of roots, stems, leaves, and fruits. Pectin is widely used in foods such as ice creams, fruit juice for their gelatinization and emulsification properties. The amount of food gelling and their characteristics could be varied with different degree of pectin esterification.

Proteins are widely used in encapsulation for their solubility, emulsification, oxidation resistance and are biodegradable. They also aid in pH-controlled release conditions in specific situations. In comparison to animal proteins, plant proteins are environmentally friendly (2).

Yeast cells are lighter in flavour and odour, which will disperse well in water, having strong adaptability to the environment. Another major advantage of yeast cells is that they can be cultured on a large scale. The following characteristics of yeast cells offer an additional edge compared to other microcapsule materials. Firstly, a natural double-layered structure can avoid volatilization loss of aromatic substances and oxygen invasion. Secondly, yeast cells do not require any other additives during the preparation of microcapsules. Thirdly, quick or long term release of core substances without breaking the wall. Finally, yeast cells are safe and nontoxic, becoming an eco-friendly microcapsule wall material.

Vitamins and minerals are the most common ingredients utilized for the encapsulation of functional food and dietary supplements. Vitamins are functional ingredients that can be used in food to incorporate specific nutritional properties and thus involving targeted delivery and controlled release. Following vitamins, there has been an increasing demand for encapsulated flavours for prolonged release of taste and fragrance. If we consider dietary supplements, for the developed and developing countries, vitamins, enzymes and minerals are the major constituents.

Microencapsulation techniques and trends

Probiotics encapsulation, multiple emulsions, cell electrospinning, and spray chilling are considered to be the future trends in the food and beverage development of the microencapsulation market.

Melt dispersion technology is commonly used for the stabilization of aroma and flavours in oils. Extrusion and emulsification techniques are used to produce gels to achieve a protective layer, antioxidant properties of plant oils or extracts. Microemulsions are used to encapsulate polyphenols and essential oils, aiding compounds such as liposomes to provide stability and targeted delivery. To achieve targeted delivery with controlled-release, fluidized bed technology can be used. To incorporate lipids in hydrogels, complex systems need to be used. These delivery systems release multiple active ingredients for long-lasting sensorial experience and organoleptic characteristics (3).

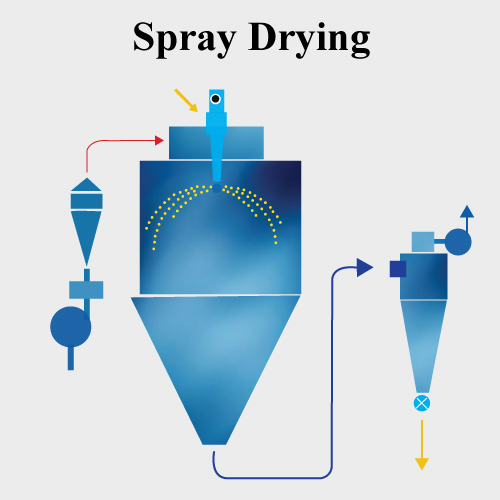

Spray Drying – One of the most dominant microencapsulation technique used in the F&B Industry, such as in milk powder, starch, spices, cereals, coffee and tea. Compared to other techniques, spray drying, chilling, and spinning are the most widely used techniques in which the active materials are suspended in the water to make the slurry. This slurry is then allowed to atomize at a heated temperature. Various physiochemical reactions occur, such as hydrophilic-hydrophobic interactions between the cell wall, active ingredient and water. Firstly, the slurry forms into micelles, then into small-sized droplets, which eventually turn into hardened shells encapsulating the entire active ingredients.

Emulsion Techniques is the fastest-growing encapsulation technique, in which dripping, polymerization, sol-gel encapsulation and coacervation are leading the trends in food encapsulation. This technique is useful for liquid, solid, hydrophilic, and lipophilic materials to achieve low particle size distribution. Encapsulation of probiotics is one of the key applications of emulsion technology.

Freeze-drying involves sublimating the ice into vapour under specific high-vacuum condition upon quick freeze. The sublimation process removes heat and runs the entire process cool, preserving the activity of active ingredients and biological samples, such as proteins. However, caution must be taken during the freezing process as the formation of ice crystals might destroy the integrity of the cell membrane.

Future Research & Development in Microencapsulation

Microencapsulation has greatly evolved from a basic preservation technique to complex technology, with properties such as taste & colour masking, controlled release, and targeted delivery. Using the microencapsulation technique, ingredients such as omega-3 fatty acids can now be easily incorporated into food products, which was formerly difficult. Corporates such as Sensient Technologies has actively involved in the development of encapsulated ice teas and soft drinks with and without carbonation. Lycored Corp. (Israel) has launched microencapsulated natural carotenoid and vitamins. Future research should focus on capsule size reduction for improved bioavailability. Continuous improvement and simplified process innovations will result in cost savings and making it more incentive for food development company to adopt microencapsulation.

References

- Yang, M., Liang, Z., Wang, L., Qi, M., Luo, Z., & Li, L. (2020). Microencapsulation Delivery System in Food Industry-Challenge and the Way Forward. Advances in Polymer Technology, 2020.

- Jackson, L. S., & Lee, K. (1991). Microencapsulation and the food industry. Lebensm. Wiss. Technol, 24(4), 289-297.

- Yoshizawa, H. (2004). Trends in microencapsulation research. KONA Powder and Particle Journal, 22, 23-31.