Specific characterization of making small-batch food with the quality of food sampling, advancement and marketing testing for restaurants and hotels

In brief:

- Small- batch food which can be easily produced in limited quantity using traditional method without less effort.

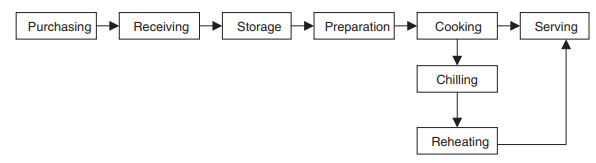

- There are several steps in making small-batch foods such as quality checking, testing, and marketing in restaurants and hotels, etc.

- Forstart-ups manufacturing in order to undergo Sampling and testing on small-batch, we have more experts. The food research lab will help to deliver more specific services like marketing and testing the products.

Introduction:

Small batch food/batch cookingis also known as boundary cooking in terms of preparing new food product in small amounts. Every food doesn’t require batch cooking so the management must be able to produce a wide range of stock in small batches and small production cycles. Batch cooking conserves a food condition which adds to itspresentation, texture or flexibility, seasoning, and nutritional values. In a large scale, more foods are hugely affected by preserving them for longer time. Small batch cooking also reduces waste and food costs.

Specific characteristics involved in making small-batch food:

The specific characteristic involved in small-batch food is itsreduced cost which in turn increases the profit. The first development of products should be tested among publics/ people and then collect its review based on flavour, textures, and appearances. The batch size should be determined from financial operation. Review the deals with the authorities to scale up your new food product development, and get approved for your recipe from higherofficials so as to avoid unnecessary problems like safety and quality issues. Then finally determine the cost based on ingredients improvements and scaled-up recipe.

The importance of quality assurance in food sampling:

Small and medium-sized food processing trade all over the worldso it is necessary to consider its quality and durability during manufacturing. The consumers and the users are enhancing more attentive importance in safe and high-quality products. Before promoting the products, the quality should be thoroughly checked. Some of the examples using baked goods clarify the difference between quality sampling and quality assurance. Consider bakery as an example in which bread should be white, with loaf volume and excellent flavour and taste. Then the producer should focus on the process so that the raw materials are handled to produce uniform products with averageamounts and characteristics. Quality of food sampling is carried out by analysing the raw materials to ensure that the products are good in conditions, and no inferior qualityused. The standards are measured correctly according to their requirements etc. However, these quality sampling food approaches, focuses on the process to avoid the complication that customer may face followed by the production and distribution chain.

Advantages of small-batch food:

- The advantages of small-batch food production are that its economical to produce a whole batch rather than a single apparatus that can be used more productively.

- It reduces cost, minimises the working time and processes while preparing the foods

- It would be more exact which gives exact sample products with less damaged products.

- The communityuses a variety of products.

- Another main advantage is that it reduces its risk by simply producing one product at a time.

- The overall wastages are lower by producing the exact number of products as required.

- Helps to plan with the probability

- The machinery doesn’t remain continuously active hence costs can be reduced.

- The small-batch foods can be produced when the demand is required or not required, but in large scale it is impossible.

Small batch food marketing and testing for restaurants and hotels:

Marketing testing depends on different factors like investment cost, risk and time pressure. The high investment will lead to high risk were the chances of failure is high. In extension, food marketing involves another kind of challenges, such as dealing with decaying products whose quality and availability vary as an on-going current producing condition.

The marketing channel and the following link is particularly important. Today processing and new circulation options provide increasing chances available to food marketing to give the consumers with applications. Then the fresh ingredients are properly being allowed into the foods and beverages, and it will differ across countries and certainty among smaller regions. Testing can be done along with such development efforts. The product quality and appeal are based on the tastes, look, feel, and packaging of foods and beverages that can impact consumer choices.

Conclusion:

In summary, the specific characterization of making small-batch food with the quality of food sampling, advancement, and marketing testing for restaurants and hotels, by food research lab helps you to fill the gap by producing the samples for making small-batch foods. To reduce your pressure, food research lab helps to develop the start-ups by providing food products for Sampling, promotion, or market testing, and gives the required quantity of expected outcomes.

References:

- Brannmark, M., Langstrand, J., Johansson, S., Halvarsson, A., Abrahamsson, L. and Winkel, J., 2012. Researching Lean: Methodological Implications of Loose Definitions. Quality Innovation Prosperity, 16(2), pp. 35-48.

- Jaroslava, E. and Noskievicova, D., 2015. More Advanced Methods of Statistical, Process Control. Prague: Grada Publishing.

- Juhaszova, D. and Cicka, M., 2018. Measurements and Data Processing in Short, Run Small Batch Mixed Production. In: Faculty of Materials, Metallurgy and Recycling Technical University of Kosice, Metallurgy Junior 2018 Proceedings.

- Herľany, Slovakia, 10-11 May 2018. Kosice: Technical University of Kosice.

- Juhaszova, D., and Zgodavova, K., 2017, short Run Small Batch Mixed Production Statistical Process Control. In: Faculty of Materials, Metallurgy and Recycling Technical University of Kosice, Metallurgy Junior 2017 Proceedings, Kosice: Technical University of Kosice.

- QI-Macros, 2018. QI Macros SPC Software for Excel. [online] Denver: Know Ware International.