Optimizing Compliance: Streamlining USA Food Manufacturing Standards

Streamlining USA Food Manufacturing Compliance Standard

Last Updated: 04/04/2024

Introduction

Safety and Quality are critical factors in any industry, more so in the food sector. Food must meet strict standards for quality and safety throughout the whole production process and up until human consumption, as demanded by both consumers and health authorities. In the event that an issue arises, it is imperative to promptly pinpoint its origins and find a solution. As a result, the food industry has a vast array of certifications and standards that ensure food safety and make it appropriate for specific customer groups to ingest.

Documents known as certifications attest to the applicant organization’s compliance with a number of conditions, some of which may be voluntary in character as well as legal or regulatory in nature.

Hazard Analysis Critical Control Point (HACCP)

Under the HACCP management system, biological, chemical, and physical dangers are prevented from contaminating the finished food product through risk-based preventative controls. When used appropriately as a control procedure, HACCP will help prevent, eliminate, or reduce dangerously high levels of known and anticipated food pollutants. The FDA Food Safety Modernization Act (FSMA) and the Safe Food for Canadians Act (SFCA) are examples of HACCP legislation. When it comes to guaranteeing the safety of food, this method seems to be far more successful than conventional visual inspection techniques. While standard inspection and testing processes are not intended to identify and manage pollutants that are intermittently distributed throughout foods and are not apparent, the HACCP system establishes methods to control food safety threats. For food hazards that are biological, chemical, and physical to be effectively controlled, HACCP certification is a globally recognized standard. Adherence to HACCP will revolutionize brands, facilitate a successful launch strategy, and provide new commercial prospects. An organization’s dedication to food safety is reaffirmed through inspection and validation by independent certification authorities.

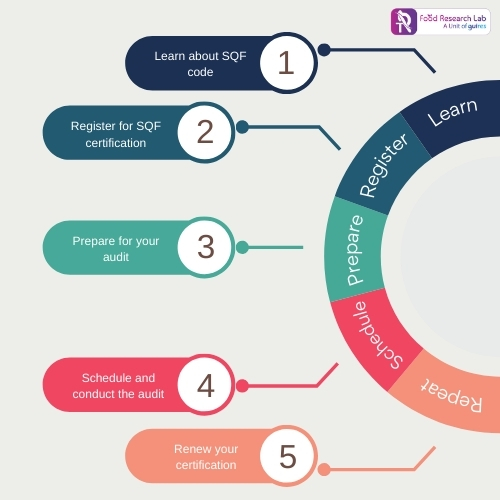

Safe Quality Food (SQF) Certification

Retailers, brand owners, and food service providers all around the world accept the Safe Quality Food (SQF) Certification as a reliable program for certifying food safety and quality. All facets of the food supply chain, from the farm to the retail outlets, are intended to meet industry, consumer, and regulatory standards through the use of the SQF family of food safety and quality rules. Food manufacturers can reassure consumers that their goods satisfy the global food safety standard, as recognized by the global Food Safety Initiative, by obtaining this stringent farm-to-fork food safety and quality certification. SQF Certification is a complete solution to help you confirm and demonstrate that quality control and food safety are applied, validated, and overseen in an efficient manner. Strong SQF Programs lead to safe products, confident brands, and satisfied customers. As of May 2021, Edition 9 of the SQF Food Safety Codes is the most recent version. In total, there are 11 codes:

- Dietary supplement manufacturing

- Aquaculture

- Primary plant production

- Food manufacturing

- Quality code

- Animal product manufacturing

- Pet food manufacturing

- Storage and distribution

- Primary animal production

- Animal feed manufacturing

- Manufacture of food packaging

FDA Regulations & GMP Certifications

Before starting any of these operations, facilities that produce, prepare, package, or store food meant for human or animal use in the US are required to register with the FDA. With the exception of facilities that are expressly exempt under 21 CFR 1.226, all facilities that carry out these activities are subject to the registration requirement. The FDA developed the Good Manufacturing Practice (GMP) certification to recognize producers who guarantee product quality by the establishment of precise protocols, their documentation, and comprehensive operator training. The primary goal of GMP is to maximize outcomes while lowering risks associated with the manufacturing, processing, and packaging of food, drink, pharmaceuticals, and medical equipment.

GMP laws cover a wide range of topics, such as addressing complaints, sanitization, personnel qualifications, record keeping, and equipment verification. The application of these standards can be somewhat flexible to accommodate the particularities of various food and beverage enterprises, and as with HACCP, the certification is intended to be in compliance with Global Food Safety Initiative (GFSI) requirements.

ISO 22000

The purpose of ISO 22000 was specifically to guarantee the safety of those who are associated with the food industry. It offers a framework for quantifying and evaluating food safety performance and hazards, encompassing every link in the supply chain. Your capacity to adhere to HACCP food safety guidelines, sanitary standards, and a strong food safety management system is validated by ISO 22000.

Food safety systems, like ISO 22000, give businesses a set of guidelines and practices for properly assessing and evaluating food safety risks and hazards. Due to its international recognition and foundation in the Annex SL framework, which includes the continuous improvement approach, ISO 22000 is the most preferred certification for the food business.

An ISO 22000 certification offers numerous advantages, some of which may differ according on the area of the food industry you work in. The general advantages that an ISO 22000 can provide are summarized as follows:

- Allows you to see a thorough, methodical, and proactive way to recognize risks to food safety and put in place efficient countermeasures.

- You can more readily adhere to the Hazard Analysis and Critical Control Points (HACCP) principles when you use ISO 22000.

- Adherence to the most recent food safety regulations on various continents

- Enhanced food chain traceability, effectiveness, and ingenuity

- Permits you to take part in global food chains on a huge scale, which can help you expand into new markets abroad.

- All techniques, methods, and procedures will be meticulously and methodically documented in ISO 22000.

BRCGS

BRCGS stands for British Retail Consortium Global Standards. GFSI has acknowledged it, and most food manufacturers and merchants around the world accept and adhere to it. As a result, it not only serves as a reliable benchmark but also fosters accountability, trust, and quality assurance.

In order to guarantee and manage product safety, integrity, legal compliance, and quality, BRCGS offers an organized framework. It facilitates the simplification of the management of operational tasks, such as the production, processing, packing, and handling of food and food ingredient inventory. Benefits of BRCGS certification are as follows:

- Offers the GFSI accreditation, which is widely accepted and regarded as a standard.

- Decrease in product rejections, returns, and complaints.

- Wide range of product safety, hygienic practices, and quality.

- Encourage waste reduction, better efficiency, and ongoing development by empowering the business culture.

- Comply with client specifications when evaluating and approving providers.

Conclusion

It takes a great deal of preparation and knowledge of the appropriate licenses and regulations to enter the US food industry. By developing a food safety management system, working with qualified experts, and keeping proper documentation, businesses can successfully introduce their products to the US market. In addition to protecting the public’s health, maintaining adherence to these standards will help businesses gain a competitive edge in this profitable industry and win over customers. Businesses that take proactive measures to ensure food safety and prepare carefully can benefit from the opportunities presented by the growing US food industry.

To make the whole process hassle-free and smooth, Guires FRL CDMO offers a holistic support service, guiding you through every phase of the regulatory process and saving you all the troubles. Our dedicated team of regulatory experts and multilingual team are highly knowledgeable and updated in regulatory laws across the globe, providing you access to all important information from any part of the world.

References:

- https://www.sqfi.com/docs/sqfilibraries/blog-documents/sqfi-guide-to-food-safety-certification-brochure.pdf?sfvrsn=beeb2642_9

- https://www.ncbi.nlm.nih.gov/books/NBK209121/

- https://www.fda.gov/food/current-good-manufacturing-practices-cgmps-food-and-dietary-supplements/good-manufacturing-practices-21st-century-food-processing-2004-study-section-1-current-food-good

- https://www.food-safety.com/articles/5141-the-benefits-of-iso-22000-to-the-food-industry#References

- https://www.iso.org/iso-22000-food-safety-management.html#:~:text=Why%20ISO%2022000%3F,ensure%20that%20food%20is%20safe.

- https://www.brcgs.com/