Healthier Ready-To-Cook food formulations

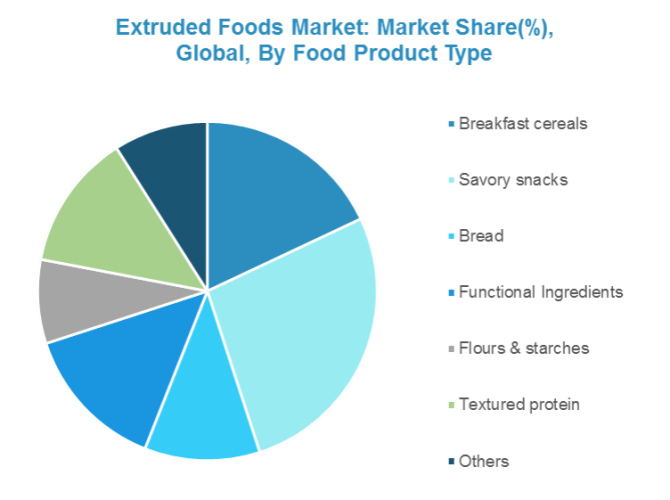

Pasta, Noodles, Macaroni, Spaghetti, the very names themselves, gives a mouth-watering feeling. It reminds one of all the tasty sauces and spices like oregano and rosemary, and cheese that go into making them. It is considered a staple food in a lot of countries around the world. Due to the current pandemic situation, it is expected to rise in the upcoming years due to changing lifestyles and people turning to more home cooking and buying less from the outside. The extruded food market in Asia-Pacific, mainly in India and China, is expected to see growth, though not so much of development in North America compared to other regions.

Source: Mordor Intelligence

The major players are some of the big names like Nestle’, Nissin Foods and Unilever. Extruded products made from whole wheat flour or all-purpose whole wheat flour along with fat, sugar and salt. In short, they are a great source of carbohydrates. But at the same time, it does not include many proteins and dietary fibre making it less healthy if too much is consumed.1

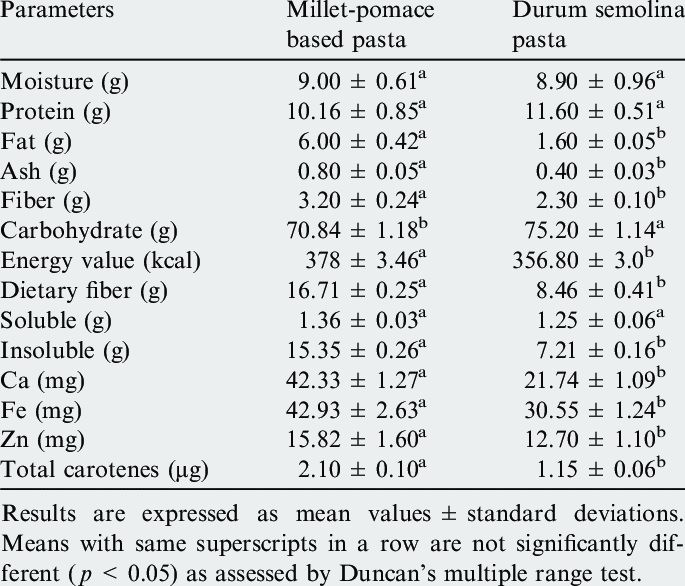

Excessive consumption of these products is leading to health problems, mainly obesity. While the nutritional requirement needs to be fulfilled in them, it is also necessary t to be appealing and tasty enough for people to consume. There has to be a balance between both the nutritional and sensory properties. This is often a challenge because there is a possibility of not getting the same sensory parameters as the ordinarily available pasta. The nutritional composition of some of these extruded products is given in the figure given below.

In a study conducted by the Department of Plant Food Technology and Gastronomy, Division of Engineering and Cereals Technology, University of Life Sciences, Poland, the addition of (1,3)(1,4)-β-D-glucans led to an increase in the water solubility index (WSI), water absorption index (WAI) and viscosity of products. Also, an increase in fat, ash, and dietary fibre content was noted. The cooking quality of the pasta was also affected, the minimum cooking time was extended, and there was an increase in loss of dry matter. Further, this experiment could influence high cooking and sensory quality. Another study where spaghetti was made using semolina showed the lowest level of stickiness and maximum hardness. The overall quality was the best, and the glycemic response was recorded to be the lowest. Hence, formulation of pasta with durum wheat with a good balance between nutritional and cooking quality could be obtained from semolina.

Another project was the production of pea- and oat rich fractions to develop an entirely new range of extruded snacks using extrusion technology. The study s held a range of (146–175 °C) as the die temperature and moisture content between (11.2 and 16.8% dry basis) seeking to maximise expansion while obtaining a good texture and pleasant sensory parameters. The product with a net moisture content of 11.2% and die temperature of 160 °C gave the best response. The resulting snacks contained 3.5 g of β-glucan per portion. It was observed to lower cholesterol and reduces postprandial glucose response. The use of high-amylose corn grits (HACG) in extruded products was also examined. The regular corn grits were kept as the control to see the variation in terms of the physical and chemical composition. It was found that the HACG extrudate had higher protein, fibre, lipid, ash, resistant starch, zein, calcium, magnesium, iron, zinc contents and 16 of 17 types of amino acids compared to the normal corn grits extrudate. Also, it was found that the sensory parameters were way better than the control sample.

The HACG extrudates had higher frangibility, cohesiveness, chewiness and overall taste with a lower coarseness and adhesiveness.5 Another study that focused on manufacturing showed extruded products using soybean, rice, finger millets, and mango seed kernel flour in different compositions increased actual proteins over the commonly manufactured products by 35.15%. The physical, functional, biochemical and sensory properties were seen to improve along with an increase in the nutritional value of the extruded product for acceptance of customer6.

The use of food industry by-products such as fruit and vegetable pomace and bagasse, oilseed cakes, oregano, carrot leaf, einkorn, tritordeum brewers spent grains, black mulberry extract-enriched pasta, finger millet pasta, fava-bean, green-pea, yellow pea, olive oil, grape marc powder in fettuccini pasta, amaranth leaves flour, Quinoa, quinoa flour, elderberry juice concentrate, green banana pulp, peel flour, buckwheat, cereal brans and whey is seen as a potential source of nutritionally enhancing and eco-friendly pasta. The intention of using the by-products is to form more eco-friendly, diet-friendly and environment-friendly extruded snacks with lesser oil sugar and salt consumption7. The quest for the best version, both nutritionally and palatability-wise, is still ongoing.

Food Research Lab can help you solve these problems. FRL is for food and nutraceutical manufacturers as well as those companies involved in NPD and developing spec without manufacturing. FRL gives you the ability to improve all phases and aspects of new product development, such as original specification, ideation, shelf-life. Additionally, you can get them out to market quicker than ever before.

References:

- 10 Improvement of nutritional and functional properties of extruded food products; Valentina Obradović;2014 Journal of Food and Nutrition Research 53(3):189-206

- Physicochemical, Sensory, and Cooking Qualities of Pasta Enriched with Oat _-Glucans, Xanthan Gum, and Vital Gluten;2020; Ada Kraw˛ecka, Aldona Sobota and Emilia Sykut-Doma´ nska

- Effect of durum wheat cultivars on physico-chemical and sensory properties of spaghetti; Lucia Padalino 1, Marcella Mastromatteo, Lucia Lecce, Sara Spinelli, Francesco Contò, Matteo Alessandro Del Nobile; J Sci Food Agric2014 Aug

- The impact of extrusion parameters on physicochemical, nutritional and sensorial properties of expanded snacks from pea and oat fractions; ; LWT, Volume 112, September 2019, 108252; CátiaSaldanha do Carmoa , PaulaVarelaa, ClairePoudrouxa, TzvetelinDessevb, KristinMyhrera AnneRiedera, HanneZobela, StefanSahlstrøma, Svein HalvorKnutsena

- Nutritional, physical and sensory properties of extruded products from high-amylose corn grits; October 2017;Emirates Journal of Food and Agriculture 29(11):846; Linsan Liu, Silu Li,Yibo Li, Yuyue Zhong

- Development of Nutrient Rich Extruded Product using Rice, Finger Millet, Soybean and Mango Seed Kernel Flour; P. S. Sapariya* , V. P. Sangani and M. H. Muliya;ijcmas.2020.907.139

- Extruded snacks from industrial by-products: A review; Simona Grasso; Trends in Food Science & Technology; Volume 99, May 2020, Pages 284-294