How to write an effective product specification sheet for manufacturing?

What is a product specification sheet?

A product specification sheet is a document that gives a detailed description of the product. It includes information pertaining to the safety and quality requirements related to its production. A product specification sheet serves as a reference for new product development, manufacturing, marketing, and quality assurance. It includes the technical requirements and the parameters that define the functionality and appearance of the product. Other names for product specification sheet are ‘product specs’ or just ‘specs’.

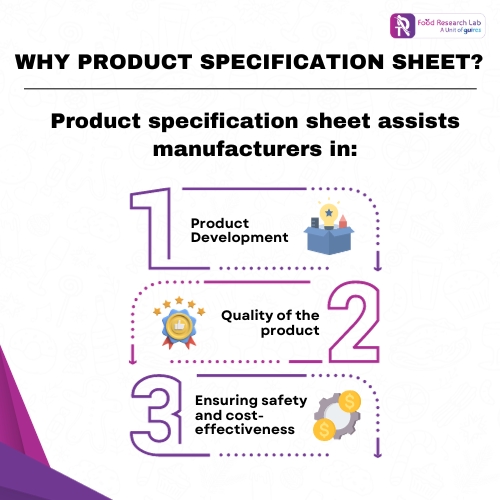

Why is a product specification sheet important?

A comprehensive product spec sheet can assist companies analyse several product options, conduct testing and certification, and address any difficulties that arise during manufacturing. Product specification sheet assists manufacturers and start-ups in the following:

- Product Development: A product specification sheet details all the essential information to the production team about the product, such as what the product is, the target audience and the product value.

- Quality of the product: A product specification sheet can help manufacturers gain valuable information about the sensory properties and any modifications, if required.

- Compliance with Safety: An accurate product specification sheet ensures the safety of food and other consumer products. Manufacturers can demonstrate that the product meets industry-specific guidelines during the manufacturing process. The more accurate the product specification form, the greater the quality of the product.

- Cost-effectiveness: Product specification sheets ensure that the right ingredients are used, and the right processes implemented while manufacturing a product. Unnecessary expenses incurred because of incorrect or incompatible materials or manufacturing methods that are not efficient.

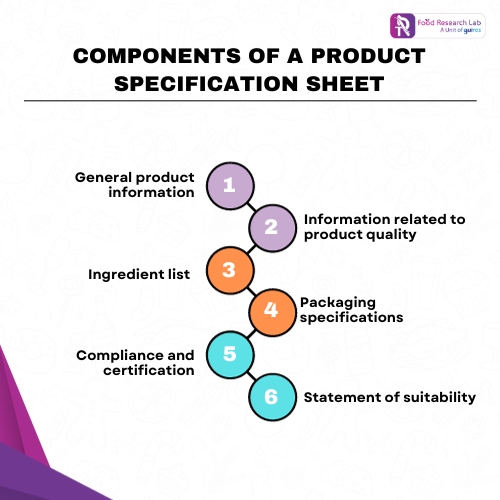

What should a product specification include?

A well-written product specification sheet consists of the following:

- General product information

General information such as product name, reference images of the product, target consumer, manufacturer details, product code and country of origin.

- Information about product quality

The processing methods, size and weight of the units and the sensory properties of the product are detailed in this section.

To know more about the various methods used in food processing, check out our blog.

- List of ingredients

The list of all ingredients, including additives, allergens if any, and their nutritional information is present in a product specification sheet.

- Packaging specifications

This section includes directions for storage, price per unit, details about product design, materials and dimensions of packaging and shelf life of the product.

- Compliance and certification

The sheet must specifically mention the various tests done and a statement that it complies with the international regulatory standards, like FDA, EFSA and FSSAI. Product certifications is also included, like halal, kosher, organic and Non-GMO.

- Statement of suitability

A statement indicating the suitability of the product- such as it is suitable for vegetarians, vegans, lactose intolerant and those allergic to nuts.

A Guide for writing a product specification sheet

Writing a product specification sheet includes all the essential information that shoul0d be included in it. Here is how to write one:

- Product Details:

The name of the product, along with the category should be included. Also, provide a detailed description of the product, including its features, functions, and other relevant information.

- Product Specifications:

The technical aspects of the product, such as its ingredients, weight, functions, and other relevant information.

- Specifics of Production:

Create a step-by-step or broad description of how the product is developed in this section. Precautionary measures, corrective measures, and other supporting processes may also be included in a detailed product specification sheet.

- Nutritional information:

Give a thorough nutritional breakdown for each portion or quantity that is requested. Include calorie, macronutrient (protein, fat, carbohydrate) information, vitamins, minerals, and any other essential nutritional components.

- Details about product packaging:

Describe the product’s packaging materials, whether plastic, glass, or anything specially manufactured for the goods. Provide the packaging material’s dimensions and total weight.

Include the product’s shelf life or expiration date, as well as its storage requirements.

- Allergens and dietary information:

Always include a list of any allergenic ingredients that may be present in the product. This is an important aspect of food safety. Consult local health standards to determine which food items are key allergens.

Indicate whether the product is suitable for special dietary preferences or restrictions, such as vegetarian, vegan, gluten-free, and so on, in addition to allergen information. This data will assist the team in managing production.

- Regulatory compliance and product certifications:

Include relevant details about compliance with local and international regulatory standards. In addition, labels like Non-GMO and organic certifications.

Conclusion

A product specification sheet provides detailed information about safety, quality, and technical parameters crucial for new product development, manufacturing, and compliance. Its significance lies in providing comprehensive information about safety and quality requirements, technical specifications, and parameters defining a product’s functionality and sensory profile. Writing one involves detailing product specifics, production processes, nutritional information, packaging details, allergens, and regulatory adherence. Ultimately, it serves as a comprehensive guide facilitating product development in line with industry standards and consumer needs.

How Guires FRL Contract R&D can help

Guires FRL offers end-to-end solutions for contract manufacturing for food, beverages, nutraceuticals, pet food, cosmeceuticals, and herbal products. Our team emphasises quality control, ensuring compliance with industry standards and regulations. We adopt a flexible approach which accommodates varying production scales while optimizing costs without compromising quality. We integrate innovation and technology in our services, fostering production efficiency and guaranteeing success in our clients’ endeavours.