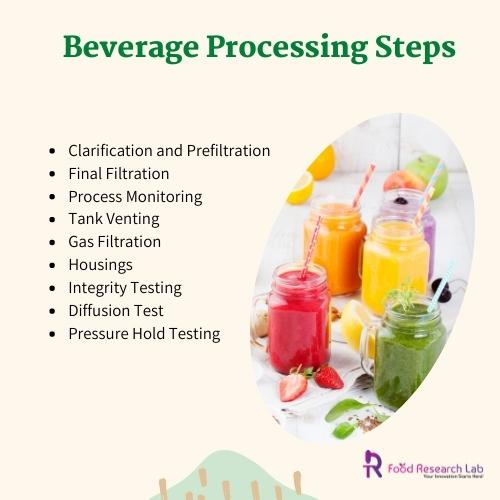

Beverage Processing Steps

Clarification

Unwanted particles can degrade the quality of your downstream product and clog your membrane filter, limiting its efficiency and lifespan. Clarification and prefiltration are essential processes in the process that eliminate impurities early on, improving the life of your final filters. The cost of prefilters is significantly less than the cost of extending the life of your more expensive membrane filters.

Filtration

Membrane filtration in your beverage manufacturing process ensures that all particles and bacteria are eradicated. Final membrane filters are helpful as a microbial barrier in a multi-barrier process because they successfully eliminate 99 to 100 per cent of unwanted microbial content.

Process

Every step of your process must verify that your product is free of microorganisms and other impurities.

Gas filtration

In your manufacturing environment, the air is one of the most significant sources of possible contamination. If the air used in your process is contaminated, your product’s quality may be jeopardized, and its shelf life may be shortened.

Particles and microorganisms must be free of particles and microorganisms in the air used to blow the bottles and CO2 or any other gases supplied in specific process steps.

FRL: To meet the demands, experts at a food research lab, ready to support you with services like feasibility, formulation, sample development and recipe optimization. While developing a healthy beverage, our food experts keep in mind that ingredients are Generally Recognized as safe.