Introduction

- The consumers are tempted to try deep-fat fried products, owing to their unique flavour, texture combination, which ranges from potato chips, French fries, doughnuts, extruded snacks, fish sticks and the traditionally-fried chicken products [1].

- Vacuum Frying is achievable at lower temperature as compared to conventional frying and therefore vacuum-fried products tend to possess better nutritional quality, owing to retention of essential phytochemicals and essential nutrition, enhanced colour due to lesser oxidation and oil degradation that is much lesser than normal frying, due to low-temperature processing.

- Frying is an indigenous method used in food processing, where lipids are used as heat transfer medium that comes in direct contact with food. There are different methods of frying such as pan frying, stir frying and deep frying.

- Conventionally, a fried product may contain as high as 40% oil, which affects the product characteristics and also the high lipid content of the fried product. This leads to number of health diseases in human-beings [2].

- Hence, there is an increased demand for healthy snack products with good taste, texture and appearance.

- Vacuum frying offers an opportunity to design a applied to produce fried products that contain less fat, low calories, less oil absorption, while at the same time containing health promoting properties.

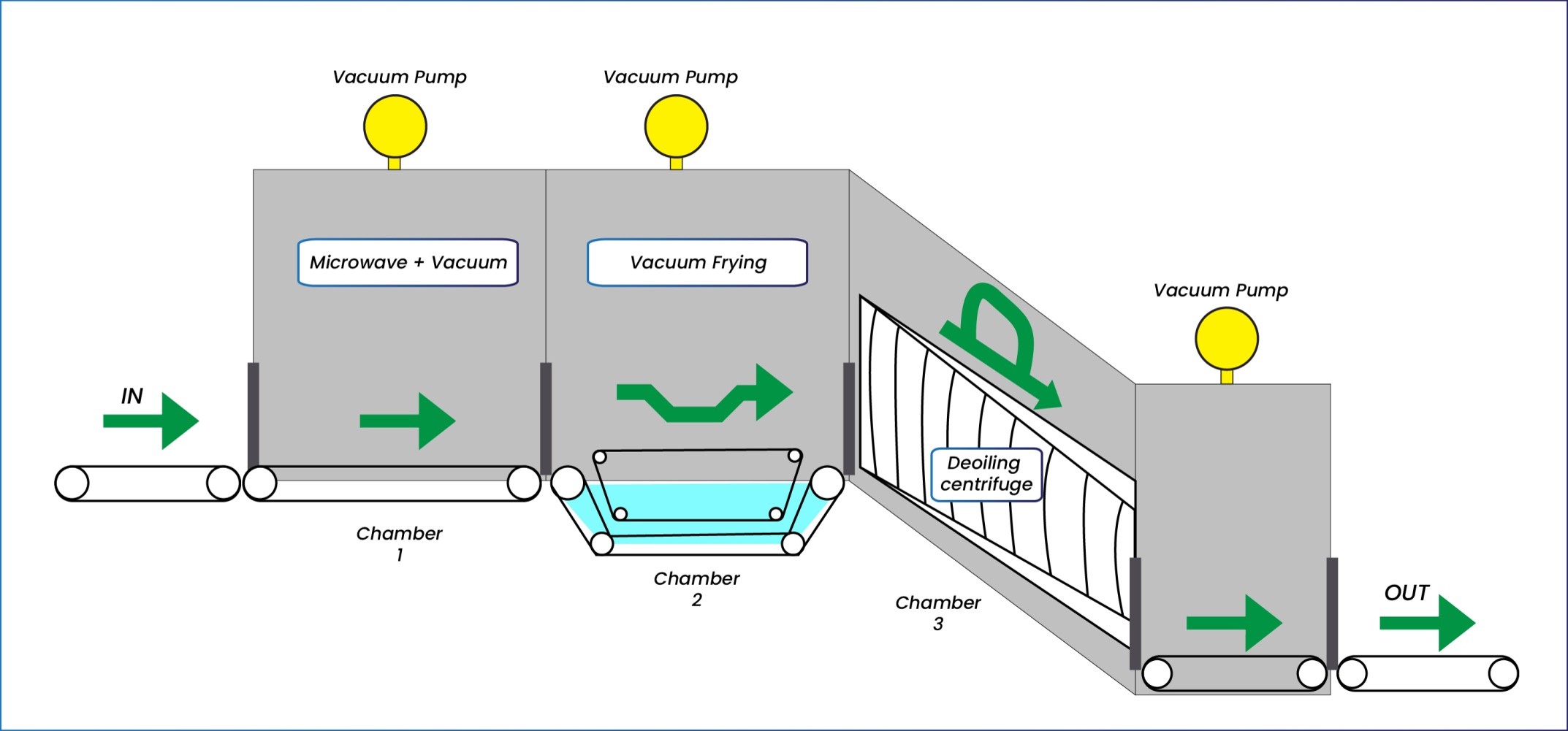

WORKING OF VACUUM FRYING

Vacuum frying machine utilizes three different stages for processing:

- The pre drying stage – carried out by vacuum to microwave drying of product to desired moisture content for frying

- Second stage – Multi zone fryer – utilizes submerging of product in complete vaccum in the oil at desired temperature and frying time.

- Final stage – The de oiler consist of a centrifuge to remove any free oil from the product [3].

- The main thing is to use conveyor belts is continuous wire mesh to move the product from one stage to another to provide maximum heat and mass transfer through it.

- This will require maintaining a vacuum through out the system.

- This can be done by using three separate chambers with sluice gates. The gates will open/close for product’s entry/outlet.

Vacuum Fried Chips

Vacuum Deep Fried Chips

BENEFITS

vacuum frying qualities:

- Vacuum fried chips retains more carotenoid than atmospheric fried samples after processing.

- Colour properties of vacuum fried samples are better than the atmospheric fried samples.

- Vacuum fried samples are more crispier than atmospheric fried samples [4].

ADVANTAGES

| Atmospheric Frying | Vacuum Frying |

|---|---|

| Oil Uptake in vacuum-fried chips is higher | Oil Uptake in vacuum-fried chips is Lower |

| Colour of vacuum-fried products darker | Colour of vacuum-fried products was lighter |

| Carotenoid retention of was lower | Carotenoid retention of was higher |

| Oil Uptake in vacuum-fried chips is higher. Atmospheric fried food was soggy, burnt and oily | Oil Uptake in vacuum-fried chips is Lower. Vacuum fried products was more uniform and crispier |

| Oil degradation is much lesser | Oil degradation is higher |

| High acrylamide content | Low acrylamide content |

| Atmospheric fried products have high moisture content (˃0.3) and high water activity (aw˃0.3) | Oil Uptake in vacuum-fried chips is Lower. Atmospheric fried products have high moisture content (˂0.3) and high water activity (aw˂0.3) |

| Oil stability is Lower after frying | Oil Uptake in vacuum-fried chips is Lower. Oil stability is higher after frying |

Conclusion

- Vacuum frying is an ideal alternative for preparing fried snack products, which can be considered as being environmentally safe as well as a high quality end product.

- In future, the Vacuum Fried Products would be a suitable alternative for conventional fried products, owing to the presence of better nutritional and sensorial properties.

- Additionally, vacuum fried products possess lower fat content as compared to conventionally fried snacks which are much safer with little or no acrylamide formation and can be preserved for a longer period of time [5].