Techno-Economic Feasibility Study

Being in an import and export, have a thirst to start a food manufacturing unit using existing raw material? Or already into Amazon or with any other food service provider, looking to expand the number of SKUs or have an idea to start a food business but not sure where to begin? Wanted to enter into a food business focusing on a healthy and tasty product? Food Research Lab has the expertise and experience to nurture food entrepreneurs.

Food Research Lab Offers a Techno-Economic Feasibility Study on your proposed Food Processing Plant. Our feasibility report and the business plan enable food entrepreneurs to understand all the factors that will impact the food processing plant. Techno-Economic Feasibility Report allows entrepreneurs to submit it to their banks for approvals of the loans and obtain capital subsidy on the said project. The report also offers raw material procurement, machine costs, processing costs, profit and loss analyses, product pricing, business value proposition, packaging and nutrition labelling.

Food Research Lab Consultants has experience in working on more than 50+ Techno-Economic feasibility studies. Our team would be happy to assist the clients with regards to setting up the plant

Implementation Plan

Phase I. Ideation

- Primary and Secondary Market research

- Idea generation

- Concept Screening, fine-tuning and finalizing.

Phase II. Feasibility Analyses

- Techno-economic viability of the project, including profit & loss analyses report.

Phase III. Product Development

- Food Product development

- Microbiology, Shelf-Life Study, & Nutritional Evaluation as per the regulations & guidelines

- Decision on Packaging

- Pilot Study

Phase IV. Implementation

- Identification, screening and selection of Contract manufacturing

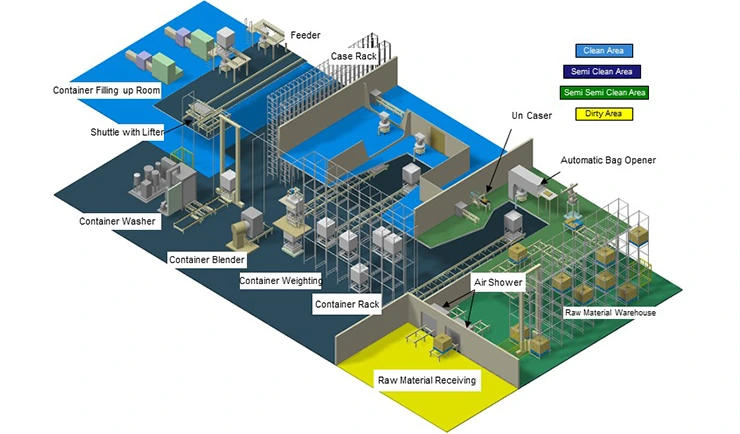

- Layout designing

- Machinery designing

- Location feasibility

- Machinery Erection & Commissioning

- Standard Operating Procedure development

- Food safety management systems development

- Trial run

- Reducing production costs and increasing efficiency