INTRODUCTION

- Scientists have recently concentrated on developing non-thermal and unconventional thermal approaches to inactivate a wide range of microbial pathogens.

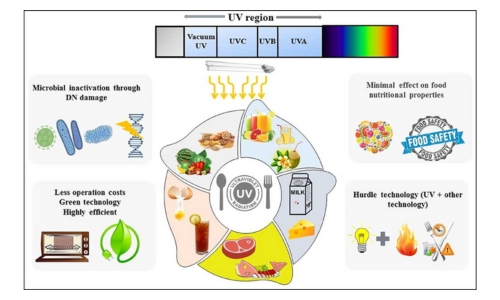

- Ultraviolet (UV) irradiation has emerged as a promising technology for food processing under real-world conditions. It is commonly considered to be a non-toxic food processing method that does not have the adverse effects derivable from more conventional options.

- UV light, particularly UVC, is well known for its germicidal ability to damage the DNA of pathogenic microorganisms.

- In the food sector, UVC light treatment has been established as a non-thermal method for treating beverages (fruit and vegetable juices, alcoholic beverages, soft drinks and many more), disinfecting milk and dairy products, processing ready-to-eat meat products, preserving food, and increasing the shelf life of fresh products.

- Recent advances in engineering have led to the development of novel UVC-based disinfectant systems with optimized intensity and better penetrability in food products than older systems.

- Apart from those applications, UVC technology in the food industry has been proven to be more effective and economical than its conventional counterpart techniques.

Figure: A schematic diagram of the applications of UV-C radiation [1].

Principles

- The principle behind UV-C light’s germicidal action is based on its ability to damage the RNA or DNA of bacteria, viruses, and fungi through interaction between the UV photons and the genetic material of these microorganisms.

- When UV-C light penetrates a microorganism’s cell wall, it is absorbed by the DNA or RNA within the cell. This disrupts the genetic material, which can lead to the formation of new bonds or the breakage of existing ones.

- This alteration results in photodimerization, where two adjacent bases in the DNA/RNA sequence bind together. This genetic damage disrupts the affected cells’ ability to replicate, rendering them unable to cause infection or pose a threat.

- The mechanism of UV-C germicidal action involves several factors, including the light intensity, exposure time, and the type of microorganism being targeted, which can vary depending on the specific application.

- Furthermore, the germicidal effectiveness of UV-C light as a disinfectant is based on the dose-response relationship, microbial susceptibility, and the optical properties of the food matrices or treated surfaces.

Advantages

- Most viruses, spores, and cysts can be effectively inactivated by UV disinfection.

- UV disinfection is a physical procedure and does not involve using chemical disinfectants. Therefore, there is no need to produce, transport, handle, or store hazardous or corrosive chemicals.

- UV disinfection is simple to use for operators.

- When compared to other disinfectants, UV disinfection has a shorter contact duration (about 20 to 30 seconds with low-pressure lamps).

- UV disinfection equipment takes up less area than other methods.

Disadvantages

- Some viruses, spores, and cysts may not be efficiently inactivated at low doses.

- In the absence of light, organisms can sometimes heal and reverse the harmful effects of UV through a “repair mechanism” known as photoreactivation.

- To control tube fouling, a preventive maintenance programme is required.

- UV disinfection can be rendered ineffective by turbidity and total suspended solids (TSS) in wastewater. UV disinfection with low-pressure lamps is ineffective for secondary effluent containing TSS levels greater than 30 mg/L.

- UV disinfection is not as economical as chlorination.

- UV-C light can be used to sanitize water used in food processing and production, as well as help prevent the growth of harmful bacteria and other microorganisms in municipal water supply systems.

- While UV-C light technology is commonly used for its antimicrobial properties in the food industry, there is also research indicating that it can be used to improve and preserve the nutritional properties of fruits and vegetables.

- When exposed to UV-C light, certain compounds in foods can be activated or transformed, resulting in the production of bioactive compounds that may have health benefits[2].

Figure : Studies on the application of IoT in different domains related to food product development [1]

Applications of UVC radiation in food processing :

- UV-C light is used to purify air in food processing facilities. UV-C lamps can be installed in air handling units to sterilize the air as it circulates through the facility, reducing the risk of airborne contamination.

- UV-C light is also used to disinfect surfaces following routine cleaning procedures in food processing facilities, including food preparation areas, packaging areas, and equipment.

- UV-C light can effectively kill bacteria, viruses, and other microorganisms that may contaminate surfaces and cause foodborne illness

- UV-C light can be used to sanitize water used in food processing and production, as well as help prevent the growth of harmful bacteria and other microorganisms in municipal water supply systems.

- While UV-C light technology is commonly used for its antimicrobial properties in the food industry, there is also research indicating that it can be used to improve and preserve the nutritional properties of fruits and vegetables.

- When exposed to UV-C light, certain compounds in foods can be activated or transformed, resulting in the production of bioactive compounds that may have health benefits[2].