INTRODUCTION

- Ohmic heating is a thermal electrical heating method. It is also called resistance heating.

- Ohmic heating is a direct heating method where food is in contact with the electrodes [1].

- The idea behind ohmic heating is straightforward. When an electrically conductive food substance is subjected to an electric current, Ohm’s law (V=IR) is followed, and heat is produced as a result of the electrical resistance of the food.

- The product may be heated to a sterilizing temperature of up to 140 °C in less than 90 seconds even though it contains big particles up to 2.5 cm in size that would be damaged in traditional equipment. [2].

- It is regarded as a sustainable food processing method.

WORKING PRINCIPLE

Ohmic heating operates on the basis of Ohm’s Law. [3].

That is V= I*R

Where V is voltage(Volts), I is the amperage(amperes), R is the resistance(ohms)

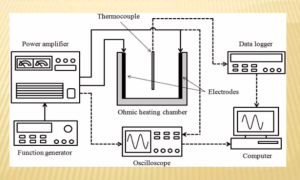

It contains three parts:

- Power supply

- Heater assembly

- Control panel

MECHANISM

- Electrical conductivity influences Ohmic Heating.

- Food is heated by electric current when it flows through it.

- Substances like acids and bases facilitate conductivity, which may not occur in fats.

- As a result, the material’s conductivity varies with the type of food.

Ohmic heating process diagram[3]

APPLICATIONS OF OHMIC HEATING

- The Ohmic heating technology enables the manufacture of new, high-value, shelf-stable goods with a quality previously unachievable with alternative sterilization processes[3].

- Ohmic Methods offer a shorter drying time and a reduction in solute loss.

- It is also applicable for specific food products like meat(uniform heating), fish(no change in water-soluble protein), milk(effective pasteurization with no additional protein destruction), fruits (Juice extraction, Juice preservation), vegetables (Blanching), egg(pasteurize egg, Reduce fouling)[4].

ADVANTAGES OF OHMIC HEATING

- The temperature required for UHT processing can be achieved.

- No problem of surface fouling or overheating of the product.

- Useful in pre-heating products before canning.

- Energy conversion efficiencies are very high.

- Suitable for continuous processing.

- Ohmic heating is more economical than microwave heating and conventional heating.

- Large-scale processes can be carried out in heavy–duty ohmic cookers or batch ohmic heaters.

- It has a high solid–loading capacity.

- Ohmic heating causes less nutrient loss.

- It provides a rapid, uniform treatment of liquid and solid phases with minimal heat damage.

- Less maintenance cost.

- Eco-friendly.

DISADVANTAGES OF OHMIC HEATING

- Lack of generalized information.

- Fat-rich food may not be heated with Ohmic heating since it is a poor conductor of electricity.

- Narrow frequency band.

- Difficult to monitor and control.

- Complex coupling between temperature and electric field distribution.

- It is limited to Direct Current [3].