INTRODUCTION

- Many industries, including energy production, health, computer science, communication, and food, depend on nanotechnology and nano science.

- Food products have a higher nutritional content, allowing bacteria to contaminate them easily. Microorganisms contaminate food and produce poisons that lead to various diseases in consumers [1].

- Nanotechnology makes the bio-sensing potential for use in food processing and applications possible. The one-step “turn-on” homogeneous experiment for multiplexed pathogen detection carried out using PDMS/paper/glass hybrid microfluidic biochips successfully demonstrated the increased sensitivity of these nanomaterials. This assay used functionalized graphene oxides (rGO).

- Nanoparticles are used more frequently to create detection methods for detecting food contamination, adulteration, and freshness because of their distinctive features.

- The value of nanotechnology in processes within the food industry can be judged through the consideration of its role in the betterment of edible items in terms of (1) shelf life, (2) taste, (3) food presentation, (4) nutritional content of the edibles, and (5) texture [2].

Nano sensors for chemicals, toxins and contaminants

- Only foods that are fresh and without any harmful substances and contaminants can be considered safe for consumption. Because of this, process analysis and product quality control are necessary for the food industry. Various chemical and biological nanosensors are available for detecting different types of chemicals.

- An electronic instrument called an “electronic nose” was developed using fragrance-detecting methods, with an olfactory system similar to mammals that can detect smells.

- The fundamental component of an electronic nose is a gas sensor that detects changes in odour or flavour type, quality, and amount. Due to their larger surface area than macroscopic particles, nanoparticles aid in improved gas absorption on sensor surfaces [3].

- By functionalizing a carboxylated polypyrrole nanotube field-effect transistor with the human taste receptor protein, hTAS2R38, a nano bio electronic tongue sensor for bitter taste detection, has been created. Surprisingly, the nano tongue could detect target bitterness chemicals phenylthiocarbamide and propylthiouracil with effectiveness comparable to humans [4].

- Recently, studies on silver nanoparticles were conducted that can detect pesticides on apples within minutes, but they still need to be validated in large-scale studies [5].

Nano sensors for food freshness detection

- Food components typically degrade when stored past the point of use and exposed to air and moisture. Individual package testing for food deterioration is not feasible in laboratories. In contrast, nanoparticles based on spot markers may be readily labelled on individual packages, are sensitive, and can be detected (Realini and Marcos 2014; Jiang et al. 2015).

- As food is exposed to air, it loses some of its freshness. Although antioxidants are used, they may lose their functionality, and bacteria can thrive since oxygen is present. Colourimetric oxygen indicators made from a hybrid nanomaterial of methylene blue and titanium dioxide have been developed for this.

- Trimethylamine is often created over time as a byproduct of the metabolism of animal proteins. Trimethylamine thus serves as a sign of freshness loss. Trimethylamine in fish samples was successfully detected using tin dioxide-zinc oxide nanocomposite sensors [7]

- Branched iron oxide-titanium dioxide hetero-nanostructure and zinc oxide nanoparticles with polyvinylpyrrolidone caps have also been employed for trimethylamine sensing.

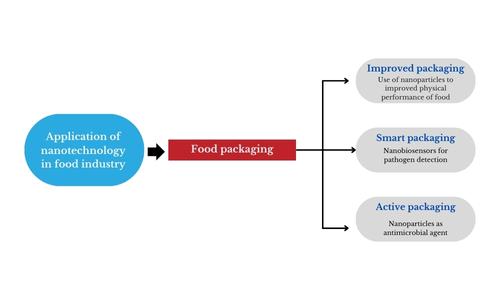

Application of Nano technology in food packaging

- Bakery and meat products have significantly benefited from the widespread use of Nano-enabled packaging technologies. According to reports, using Nanosensors, Nanocomposites, and NPs in food packaging is an effective and more genuine strategy to enhance food preservation [8].

- A polymer can be a more advantageous substitute for commonly used packaging materials, including paper, glass, and metals in Nano composite-based food packaging because of their cheap cost and efficiency.

- Nanocomposites, including cellulose microfibrils, CNTs, Nano clays, and Nano oxides, act as reinforcement for the polymer matrix in Nanocomposites. Polyamide, polystyrene, nylon, polyolefin, chitosan, cellulose, and carrageenan are a few examples of such often utilized synthetic and natural polymers in food packaging [1].

Figure 2: Nanotechnology finds its application in food packaging [9]

Figure 2: Nanotechnology finds its application in food packaging [9]

Conclusion

- In contrast to the present-day use of standard sensors, nanosensors provide quick and accurate detection of microbes, chemicals, and contaminants. Nanoparticles are also particularly helpful for identifying dietary elements that break down, such as vitamins and antioxidants.

- The different packaging strategies are crucial in maintaining quality while providing food products with the necessary considerations for customer acceptance.

- Nanoparticle technology has made it possible to artificially sense smell and taste with effectiveness comparable to that of a person. Nanoparticles are, therefore, essential to the food business.

- These dynamic synthetic molecular frameworks are an important representation in the developing area of the food sector due to the great sensitivity of nanomaterials as efficient sensors of different chemical and biological pollutants in the food sector.