INTRODUCTION

- Liposomes are tiny spherical artificial vesicles made from cholesterol and natural, non-toxic phospholipids. Liposome technology can be classified as a type of encapsulation.

- Encapsulation can be considered a method of enclosing materials into capsules before delivery into a system. Either whole cells or bioactive molecules, such as antioxidants, enzymes, polyphenols, and micronutrients, can be packed within wall materials in order to form encapsulated materials.

- According to the particle size, encapsulation technology can be categorised as microencapsulation (from 3 to 800 μm) or Nanoencapsulation (from 10 to 1000 nm). The use of Nano/microencapsulation can help bioactive.

- Lipid-based encapsulation technologies are now regarded as the best alternative for encapsulating sensitive components, with an emphasis on food and nutritional supplements that include hydrophobic and hydrophilic molecules.

- Liposome and nanoliposome techniques are often used in the food industry for nutrient enrichment and supplementation. It improves the sensory qualities and shelf life of the food product and can be used instead of microencapsulation.

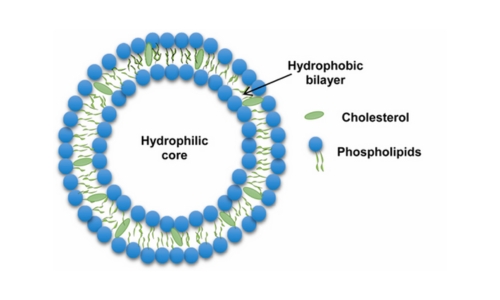

Figure 1: Figure 1: Structure of a liposome [3]

Figure 1: Figure 1: Structure of a liposome [3]

Structure of a Liposome:

- Structurally, liposomes are spherical or multilayered spherical vesicles made by the self-assembly of diacyl-chain phospholipids (lipid bilayer) in aqueous solutions.

- The bilayer phospholipid membrane has a hydrophobic tail and a hydrophilic head that leads to the formation of an amphiphilic structure [1].

Advantages:

- High bioavailability and absorption compared with other types of oral supplements.

- Micronized encapsulation protects the substance from the environment of the GI tract and promotes transmucosal (oral) uptake and absorption.

- Increased intracellular delivery.

- Can hold both hydrophilic and hydrophobic compounds.

- Best suited for those who cannot swallow a tablet.

- Facilitates incremental dosing and dose adjustment for children and adults.

- Cost-effective by being able to take a lower dose for the same effect.

Disadvantages:

- High cost of manufacture.

- Possibility of poor manufacturing (e.g. large particle size, poor ingredients).

- Possibility of instability [2].

Applications of liposomal Nano-encapsulation techniques

Food processing

- The liposomal applications have been studied extensively in dairy products in terms of stability of the food components against degradation and enhanced delivery action of the antimicrobial peptides.

- In baked food products, the use of sweeteners produces undesirable caramelization when heated, which may affect the flavour and nutrient content of the product on consumption. This can be minimized by nanoliposome applications leading to desirable liposomal flavour and nutrient ingredients for the product [3].

Nutraceutical

- Liposomes can bring significant modification in nanocarrier products by tailored product enabling systems, with numerous applications in target-oriented dietary products to the biological site inside (as the incorporation of antibodies) or outside (based on particle or cell size) the human body [4].