INTRODUCTION

- Freezing is a food preservation technique that involves decreasing the temperature to stop bacterial growth. The technique of freezing food by submerging it in an ice and salt brine has been followed for millennia in cold climates, and a patent for it was granted in Britain as early as 1842.

- Over the years, several freezing technologies have been evaluated for preserving food and other biological matters. Such as:-

Freezing by Contact with a Cooled Gas

It is known by many names, such as cabinet freezing, air-blast freezing, belt freezing, spiral freezing and tunnel freezing.

Cryogenic freezing

Liquefied gases directly contact the foods in cryogenic freezing [1].

Emerging technology

ISOCHORIC FREEZING

- Isochoric is an alternative preservation technique developed by Rubinsky and his group.

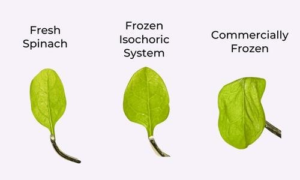

- Isochoric freezing preserves food products at sub-freezing temperatures without ice formation inside the product.

Why is it different from other methods

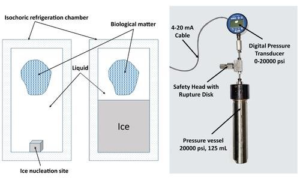

- The food product is immersed in an isotonic solution and brought to a sub-freezing temperature inside the closed chamber.

- During freezing, ice expands in volume, increasing the pressure.

- However, some volume remains unfrozen due to the Le chatelier’s principle.

- A chamber is designed for food in a non-frozen section, then preserved at sub-freezing temperature without internal ice formation.

- This separation from ice and food is impossible in the conventional freezing process.

In a typical Isochoric process,

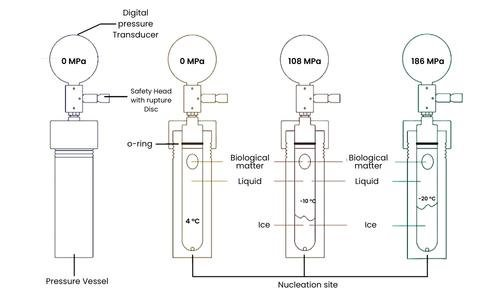

- The food material is immersed in an isotonic solution inside a rigid container capable of withstanding elevated pressure.

- Materials such as stainless steel cylinders, carbon fibre composites, and hard phenolic thermosets with pressure transducers and rupture disks are employed for isochoric processes.

- Then, ice crystals are introduced into the container as the nucleation site, and the chamber is tightly packed.

- Inserting this nucleator to preserve food materials in their aqueous phase without forming ice crystals is essential.

- The chamber is then sealed with a metal screw to restrict any air passage in and out of the container [2].

PRESERVATION OF GRAPE TOMATO BY ISOCHORIC FREEZING

- By Cristina Bilbao-Sainz et al., 2021

- This investigation looked into tomato preservation using isochoric freezing.

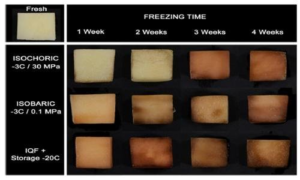

- Isochoric freezing was compared with freezing under isobaric conditions and with methods of food preservation at 10oC cold storage and quick individual freezing (IQF).

- The nutritional and physicochemical qualities were assessed.

- The findings indicate that it is possible to preserve tomatoes by isochoric freezing while keeping their physicochemical and nutritional qualities close to those of fresh tomatoes, which may have applications in the industrial preservation of tomatoes [3].

IMPACT ON ENZYME

The isochoric method helps lessen food browning. When potatoes were kept at 5 °C under isochoric refrigeration as opposed to isobaric freezing, there were noticeable differences in their colour.

FOOD QUALITY IMPACT

A constant-volume preservation method in a closed rigid container can better retain the food’s quality. For instance, potatoes lose weight at the same temperature in an isobaric freezing system. In contrast, when stored in an isochoric refrigeration system (5 °C) system immersed in a 10% (w/w) sucrose solution, potatoes experience no weight loss.

IMPACT ON MICRO-ORGANISM

Escherichia coli was shown to suffer from membrane damage, changes in the size and form of the cell, protrusions, ruptured membranes, and the outflow of intracellular materials after being isochoric-cooled to 15 °C.

FUTURE PROSPECTS

- Further research needs to be done on commercialisation since some products under high pressure have a detrimental effect.

- Studies need to be done to understand the mechanism by which delayed enzyme activity occurs. Similarly, the effects on micro-organisms need to be studied

- The focus of engineering research currently must be on simpler designs establishing procedures for extensive use.

- Improvements must be made in process economics [3].