INTRODUCTION

- Initially developed as a drying technology, Instant Controlled Pressure Drop Technology (DIC) has since been used in various other processes, including creating puffy snacks and improving texture and odour.

- Multiple traditional drying techniques can be replaced by DIC to produce dried goods of higher quality with better sensory and texture characteristics. It may also be used before or in combination with various drying methods on food products.

- DIC can be used with other technologies like dehydro-freezing, freezing, freeze-drying, and osmotic pretreatments like Moisture Equilibration Process (MEP) for dehydration preservation. By subjecting the material to high saturated steam pressure for a brief period, the thermomechanical technique called Instant Controlled Pressure Drop (DIC, or Détente Instantanée Controlée) causes instant water evaporation within the matrix.

- This procedure is regarded as a highly effective HTST-type treatment because it involves briefly exposing the material to saturated steam, followed by an instant pressure drop that causes water to evaporate, texturise and cool the product. This effect improves food drying and kills vegetative germs and spores without affecting thermosensitive molecules or the quality of the final product. The DIC method was successfully used to treat a variety of foods and pharmaceutical goods on both a lab and an industrial scale [1].

Principle Mechanism of Heating

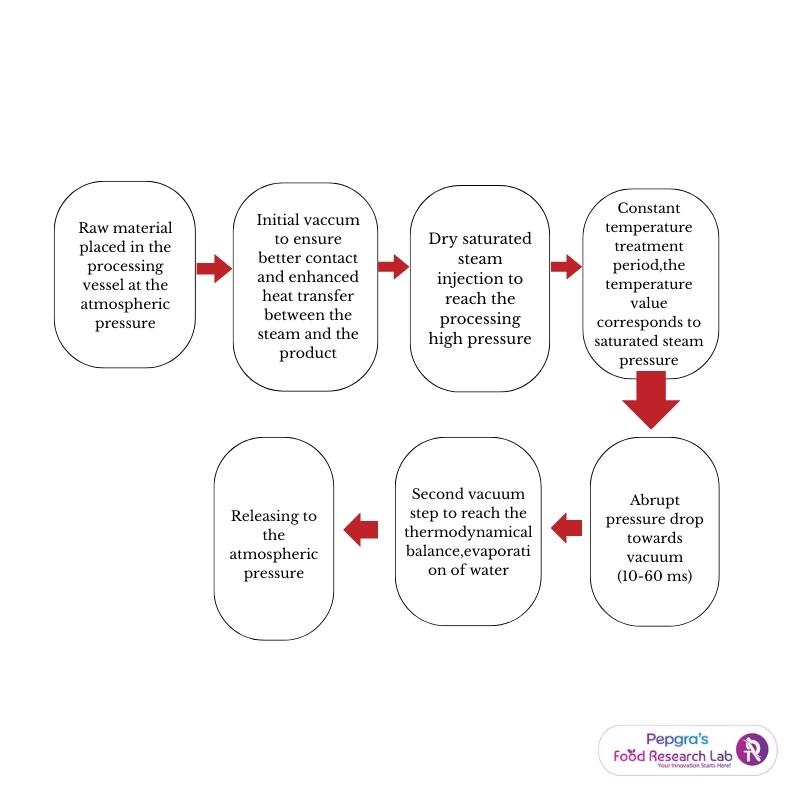

- This procedure begins with a brief heating stage (10–60 s) that includes a saturated steam injection at high pressure (up to 1 MPa) applied to a product first placed under a vacuum. In this step, the product is heated, and the vapour condensation increases the moisture content by 0.1 g H2O/g dry basis.

- The first vacuum ensures that the steam and sample make quick contact, enhancing heat transmission. Compressed air may occasionally be used as a pressurised agent for the multicycle DIC treatment. Following the initial heating step, a sudden drop in pressure (0.5 MPa/s) towards a vacuum (3-5 kPa) over just 10–60 ms causes the product’s water to evaporate automatically, creating a large amount of vapour and significant mechanical stress that allows the product to expand.

- The water’s natural evaporation also ensures quick cooling, preventing the thermal degradation of the treated products’ high-quality components. Extremely high cooling rates of 1500–2000 kW m-2 are possible. The product’s extension stress also develops a new expanded and porous structure. The improved drying process, solvent extraction, and many other functional qualities of foods are made possible by the novel structure’s increased specific surface area, mass transfer diffusivity, and product accessibility. Costs related to energy can also be decreased.

Figure 1: The process of a DIC cycle [2]

Figure 1: The process of a DIC cycle [2]

Main Components of DIC

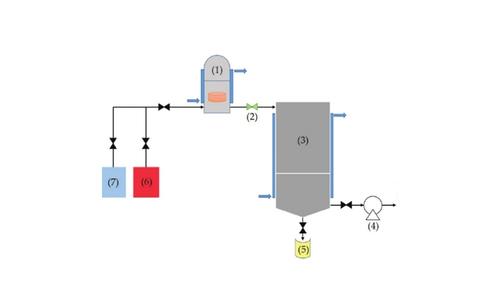

The product to be processed is placed within a processing vessel, an autoclave with a heating jacket.

- A pneumatic valve that guarantees the almost immediate release of steam pressure from the treatment vessel to the vacuum tank.

- A vacuum system comprises a cooling jacket-encased tank and a vacuum pump. The tank volume is typically 100–130 times more than the processing vessel volume, and the tank pressure is maintained at roughly 2.5-5kPa by a water ring pump.

- A condensate recovery trap for extract collection [2].

Instant Controlled Pressure-Drop Treatment on Fruits

| Matrix | Objective | Applied Treatment: Pressure; Time | Optimal: Pressure; Time | Key Findings |

|---|---|---|---|---|

| Banana (Musa sp.) | Obtain and characterise DIC Treated banana flours | 260–500 kPa; 12 to 48 s | 500 kPa, 11 s | There was a 23% increase in effective diffusivity, a 290% increase in WHC *, and a 15% OHC reduction.WHC: water holding capacity; OHC: Oil holding capacity. |

| Strawberry (Fragaria var. Camarosa) | To study the impact of DIC on the antioxidant and crispiness of strawberry snacks | 100–600 kPa; 5 s–25 s | 600 kPa; 15 s | The highest crispiness: 600 kPa, 10 s Maximum Anthocyanin preservation was noted at 350 kPa; 10 s. |

| Berry cacti (Myrtillocactus geometrizans | To preserve the antioxidant capacity of berry cacti after DIC processing | 100–450 kPa; 5–45 s | 450 kPa; 25 s | DIC was an efficient method to dry berry cacti, comparable to freeze-drying. |

| Date (Phoenix dactylifera L.) | Obtain Zaghloul Snacks and characterise them | 200–600 kPa, 9 s to 35 s | 600 kPa; 22 s | 146% expansion ratio achieved; 59% increase in colour intensity |

Instant Controlled Pressure-Drop Treatment on Fruit Byproducts

| Matrix | Objective | Applied Treatment: Pressure; Time | Optimal: Pressure; Time | Key Findings |

|---|---|---|---|---|

| Cranberry pomace and seeds | Improve the product′s nutritional, hygienic, organoleptic, and convenience attributes. | 200–500 kPa; 5–15 s | – | A remarkable increase in the kinetics of drying and rehydration was observed, and the natural taste was preserved. |

Instant Controlled Pressure-Drop Treatment on Vegetables

| Matrix | Objective | Applied Treatment: Pressure; Time | Optimal: Pressure; Time | Key Findings |

|---|---|---|---|---|

| Potatoes (Solanum tuberosum) | To confer a porous structure to potatoes by DIC texturing, thus facilitating the drying process at a lower water content | 300 to 600 kPa, 1 cycle, for 20 s | 600 kPa, 1 cycle, for 20 s | A lower value of water activity |

| Tomatoes (Solanum lycopersicum L.) | Effect of swell-drying of tomatoes slices on texture and rehydration | 100–700 kPa; 5–45 s | 400 kPa; 30 s | The firmest structure after rehydration was obtained for tomato slices and preservation of antioxidant capacity. |

Impact of Instant Controlled Pressure-Drop Treatment on Cereals Drying

| Matrix | Objective | Applied Treatment: Pressure; Time | Optimal: Pressure; Time | Key Findings |

|---|---|---|---|---|

| Rice (Oryza sativa) | Study the effects of DIC on paddy rice | 400–600 kPa; 15–40 s | 500 kPa for 16 to 30 s | 65%-time reduction in post-production cooking time |

| Wheat (Triticum spp.) | To evaluate DIC texturing on some physicochemical and nutritional properties of puffed wheat snacks products | 300–500 kPa; 3–11 s | 500 kPa for 7 min | A wheat grain expansion was obtained, as well as better sensorial properties. |

Table 1: Studies on DIC for drying fruits, vegetables and cereals [3]

Examples of swell-dried fruit and vegetable products.

Figure 3: Fruits and vegetables that can be dried by DIC [4]

Figure 2:

Figure 2: