client

Rani Drink

Our Role

We redefined fast-casual loyalty

Today’s Task

What We did Today?

Event: Clean Label Fruit Dice Beverage – Reverse Engineering of Rani Drink

Today’s task focused on developing a naturally flavoured fruit dice floated beverage, inspired by a reverse engineering approach to Rani fruit drink. Rani’s formulation includes real fruit dices and juices, with ingredients such as water, sugar, peach juice (14%) reconstituted from puree and peach dices, pear juice (2%) from concentrate, stabilizers (412, 466), acidity regulator (330), antioxidant (300), permitted natural colour (160a(i)), and nature-identical peach flavouring. The total fruit juice content is 16%.

However, our client specifically requested a healthier, clean-label alternative with a focus on minimal processing, natural fruit juice, and reduced additives. As a result, our formulation aims to incorporate real fruit juice and dices while eliminating artificial stabilizers, synthetic flavours, and additives—ensuring transparency and consumer trust in line with modern functional beverage trends.

How I Felt Before Starting – Developing a Healthy, Natural Fruit Drink

Creating a healthier, naturally preserved fruit drink with added vitamins and minerals—while maintaining its sensory quality—was both a challenging and daunting task. Formulating a clean-label beverage requires minimal processing, careful natural preservation strategies, and strict compliance with food safety standards.

Despite the complexity, my passion for food technology and processing kept me motivated. I was enthusiastic about diving into scientific research through trusted sources like PubMed, Web of Science, and food technology journals such as IIFST. With a health-focused, technically precise approach, I confidently began the formulation process.

🧪 What We Did Today

Our Product Development Plan – Clean Label Fruit Drink

Our plan included two key steps in the natural beverage formulation process:

- To develop the initial formulation once ingredient procurement was completed and client approval was obtained.

- To validate the thermal processing procedure required to ensure product safety, shelf stability, and nutrient retention in alignment with clean label and minimally processed beverage standards.

Key steps followed:

As per the client’s request, we selected four tropical fruits—Peach, Mango, Pineapple, and Orange—to be used as individual variants in our clean-label fruit drink formulation. Each fruit presented unique challenges in terms of colour, flavour, and taste, which had a direct impact on the sensory profile of the final product. Managing this diversity was one of the most demanding aspects of the formulation process.

Another major challenge we faced was the limited shelf life of the diced fruits procured from our vendors, typically lasting only 3–4 days. This required us to complete the formulation and processing within that window, adding time sensitivity to an already complex project. We’ll explore the sensory impact of each fruit and our shelf-life management strategies in future updates.

All fruits were thoroughly washed with potable water and then rinsed with 100 ppm chlorine solution, followed by a second rinse to ensure the removal of any residues. This step ensured microbiological safety before processing.

Each fruit was diced and blended individually to maintain control over consistency and flavour. Where needed, water was added to adjust concentration. We carefully monitored and adjusted the fruit-to-water ratio, pH, and °Brix levels to achieve the desired sensory experience, sweetness, and texture.

The beverages were pasteurized at 72°C for 2 minutes and then rapidly cooled to 4°C. This thermal treatment helped to control microbial growth while preserving the product’s organoleptic properties such as taste, aroma, and appearance.

A cold-fill technique was used to fill the pasteurized beverages into sterilized PET bottles, which were then hermetically sealed. The bottled samples were stored at 4°C for post-production quality assessments, including microbial analysis, flavour retention, and physical stability testing.

📚 What I Learned

- Flavor Retention Challenges: I have observed some flavors (notably orange and peach) showed mild volatility to the pasteurization temperature.

- Base Uniformity: Each fruit juice exhibited distinct behavior in terms of acidity and sweetness perception. This helped me to understand that each fruit juice base needs specific balancing and optimization strategy.

Outcome:

During the initial batch trials, the beverages exhibited natural sweetness and smooth texture. We need to standardize the color intensity and flavor profile across the four variants through optimization and preservation strategy.

✅ What Went Well

- In the initial phase, the texture and sensory profile did not meet expectations and only matched approximately 50% of the benchmark sample (Rani drink).

- However, we successfully achieved the desired shelf life, as the pasteurization process was effectively standardized.

⚠️ What Could I Have Done Better

- Flavor Balancing: Additional calibration is needed to strengthen peach and orange drink’s sensory profile.

- Stability Assessment: We observed the separation and sedimentation which needs to be standardized.

What made to choose FRL

We help you to comply with guidelines and attain certifications that you need.

What made

Choose

FRL

Caramel

Thank you for the Update and effortd caramel. We Appreciate the detailed trials and variations you've conducted. Please Ensure the flavor alignment is testes accordingly. I look forward to the final version and appreciate your continued dedication.

Project Code:24FRL-BEV-NPD 4577-01

Name:Mohammad Hassan

Pasta

Very First thing, You all should feel proud yourself that you made something that do not exist in market. Heat and eat pasta with bold flavours.

Project Code:24-FRL-FOD-NPD-2462-02

Name:Miral

Protein Biscuits

V19 plain is the best anf finalized from our side. It is accurate in taste(plain), texture, and after tastte is also not bitter at all, He loved it as a plain flavour. V19 cardomon should add more flavour rest everything is fine.

Project Code: 24-FRL-FOD-NPD-3449-01

Name: Mehul Molir

Cola

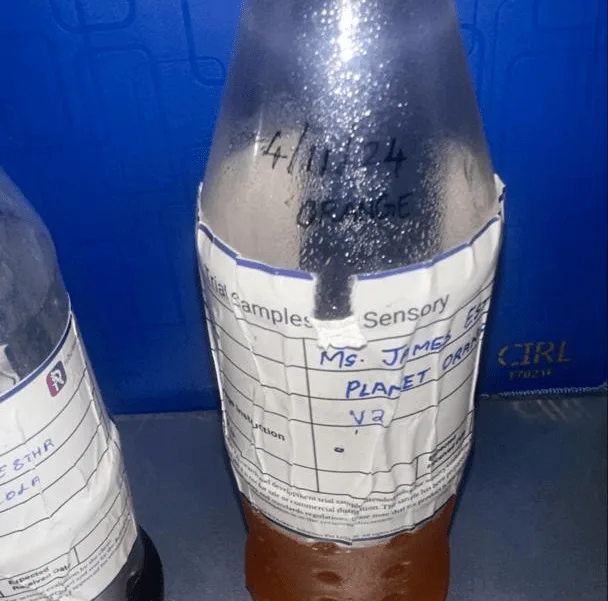

Hello, I am using the oppurtunity to appreciate the teams effort we will be picking V1 for cola, So far we don't have any complain about it, I will like to know the type of sweetner use, during the taste test some said it too sweet while some said it for orange we are picking V2, no complain too, thank you once again

Project Code: 24-FRL-BEV-REV-2878-01

Name: Esther

Energy Candy

Since a year Ago, we statrted this journey of developing energy candy and we took different steps to develop the product. I am really happy to see endless efforts you people have done to develop an energy candy, Hats off to you and your didication towards unbiased work

Project Code: 24-FRL-NPD-FTP-PMR-2660-02

Name: Harshad

Let’s create something Innovative and Delicious together

Food Research Lab strives for excellence in new Food, Beverage and Nutraceutical Product Research and Development by offering cutting edge scientific analysis and expertise.