CLIENT

Instant Tomato chutney Powder

Tomato Chutney

OUR ROLE

We redefined fast-casual loyalty

Today’s Task

What We did Today?

Instant tomato dip powder

Event: I had planned on formulating an instant tomato dip powder today.

How I felt it (initially before executing the actual task): I find the product formulation process fascinating.

Actual Task: Product formulation

What did I learn?

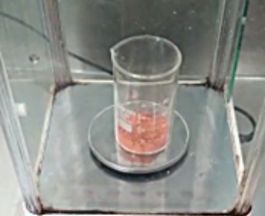

Spray-dried tomato powder was tried first for formulating the instant tomato dip powder. Ingredients like garlic powder, salt, red chilli powder and cumin seed powder were also used. The product’s sensory parameters of taste and flavour were excellent at a score of 8. However, the texture was too pasty when using spray-dried tomatoes. Later, on research, it was discovered that freeze-dried tomato powder would help achieve the desired texture but was rather expensive when enquired about the process. Therefore, another drying method was chosen, and tray drying seemed the best alternative. The equipment was affordable and convenient to use. The tomatoes were tray dried at 65oC for 4 hours and ground to a coarse powder to develop the dip powder.

Solution

What I did Today

Trial 1

Trial 2

Trial 3

Outcome :

Am instant tomato dip powder was formulated at the Food Research Lab, which is ready to mix and consume.

VideoLink: https://www.youtube.com/shorts/73xZIyfv8SM

What went well?

The tasty product had an excellent sensorial score.

What Could I have done better?

Trying other drying methods for formulating instant tomato dip powder.