DEFINITION

- High-pressure processing (HPP) is a ‘non-thermal’ technique of food preservation that uses pressure instead of heat to effect pasteurization. It inactivates harmful microorganisms that cause food spoilage. HPP allows food preservation with negligible effects on taste, texture, appearance or nutritional value since it uses enormous pressure (~ 400-600 MPa) at temperatures below 45oC.

- Other names for High-pressure processing are High-hydrostatic pressure processing (HHP), High Pressure Pascalization and Ultra-high-pressure processing (UHP).

APPLICATIONS OF HPP TECHNOLOGY

- Applications of HPP Processing include its use as a “cold pasteurization” method for fruit juices, as a means of sanitizing packaged ready-to-eat meats, and inactivation of spoilage enzymes to enhance the refrigeration shelf-life of avocados and guacamole. HPP food processing can also separate raw shellfish meat from its shell (1).

- Fruits and vegetables treated with HPP yields High pressure processing juice which preserves the sensory and nutritional properties of fruits and vegetables

PRINCIPLE

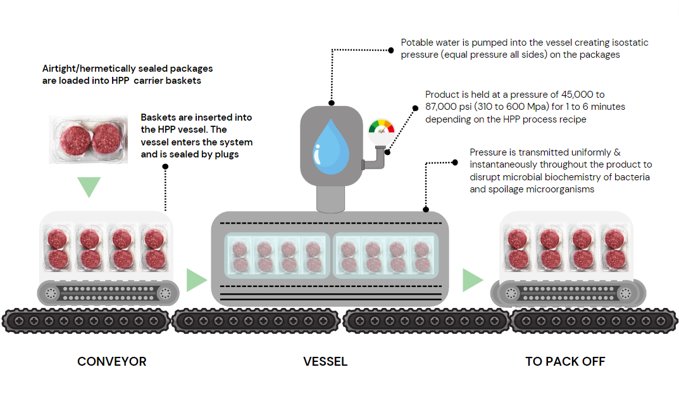

- Le Chatelier’s principle states, ‘ If a change in conditions is applied on a system in equilibrium, then the system will try to counteract that change and restore the equilibrium’. The Isostatic principle states that the HPP is volume-independent; therefore, pressure is transmitted instantaneously and uniformly throughout a sample. Pressure gradients do not exist, so the product’s size and geometry are irrelevant. Typically, HPP is carried out at 300–600 Mega Pascals (MPa) at room temperature for 2–30 min (2).

MECHANISM OF INACTIVATION OF MICROORGANISMS

- A significant function of the High-pressure processing of food is the destruction of microorganisms. Microbial cell destruction can be attributed to the following detrimental changes when pressure is applied.

- Cell membrane destruction occurs due to the irreversible structural changes of the membrane proteins and other macromolecules. There is also a disruption of homogeneity of the intermediate layer between the cell wall and the cytoplasmic membrane.

- Membrane ATPase is inactivated in HPP (3).

EQUIPMENT

Typically, the HPP equipment has the following necessary components

- A pressure vessel and its closure,

- A pressure generation system,

- A temperature control device, and

- A material handling system. Most pressure vessels for HPP applications are made from a high tensile steel alloy called ‘monoblocs’ (forged from a single piece of material), able to withstand pressures of 400–600 MPa. For higher pressures, several designs and configurations like “pre-stressed multi-layer or wire-wound vessels” are used (4).

HOW HPP WORKS