INTRODUCTION

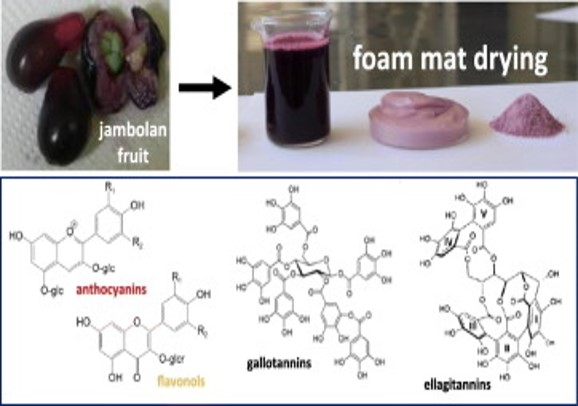

- The primary objective of food dehydration is to reduce microbial activity and product deterioration for extended shelf life.

- In addition to preservation, the reduced weight and bulk of dried products decrease packaging, handling, and transportation costs

- The terms dried and dehydrated are not synonymous. The US Department of Agriculture lists dehydrated foods as those with no more than 2.5% water (dry basis)

- Other food dehydration forms include freeze drying, spray drying, microwave drying, vacuum drying, sun drying, and solar drying [1].

FOAM-MAT Drying Processing Technique

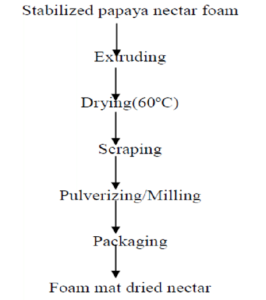

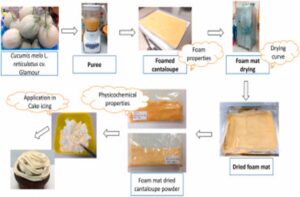

In the process of foam mat drying,

- Liquid foods are whipped into stable foams and then air-dried. Dried.

- The foams must maintain stability and preserve their characteristic properties during warm air drying.

- Open construction to make drying and de-traying more quickly .

FOAM Formation

- A thin liquid film layer called the lamellar phase separates the two phases of foam (the scattered and continuous phases, the thin wall of a bubble). According to Eisner et al. (2007), foam in food and beverages is a complicated system of gas, liquids, solids, and surfactants.

- The process of creating foam is essential. Several parameters, such as the quantity, size, and distribution of bubbles, will affect the texture of the foam; uniformly dispersed little bubbles further produce softer foams.

- The foams’ high interfacial energy makes them thermodynamically unstable. The instability can be divided into two categories: (1) unstable or transitory foams, which have lifetimes of a few seconds, and (2) metastable foams, which have lifetimes of many hours to several days [2].

Most Common Additives/ Gums / Hydrocolloids

Egg albumen foams/gels

- Foam ability and foam stability are one of the most important functionalities of egg albumen. However, the use of commercially available egg albumin for foaming poses a few disadvantages, such as limited pH and ionic strength variety for the adequate performance

- According to Kampf et al. (2003), prolonged increasing whipping time increases the number of small bubbles and decreases the number of larger bubbles without much effect on their sizes. The whipping time affects the consistency of the foam or its mechanical strength.

Methylcellulose in foam-mat drying, Methylcellulose origin and food uses

- Cellulose molecules can combine to form fibrous crystalline bundles that are highly insoluble and impermeable to water.

- MC’s heat-gelling ability makes it possible to eliminate pre-frying from the manufacturing process of battered foods.

- Temperature and pH do not significantly affect the water retention of powdered cellulose.

Gum Arabic in foam-mat drying

- Gum Arabic is also known as gum acacia. Gum Arabic also contains small amounts of protein, an important part of the structure. For example, a combination of Arabic gum and other gums, such as (tragacanth gum) at a specific ratio, can produce a thin emulsion with minimum viscosity of high quality, shelf and stability [3].

FOAM MAT DRYING PROCESS