INTRODUCTION

Extraction is the initial stage in separating the desired natural products from the base materials.

The common types of extraction are-

- Solvent extraction

- Distillation method

- Pressing

- Sublimation

GENERAL STAGES OF EXTRACTION

- The solvent penetrates the solid matrix,

- The solute dissolves in the solvents,

- The solute diffuses out of the solid matrix, and

- The extracted solutes are collected [1].

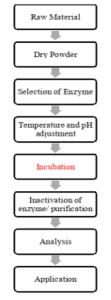

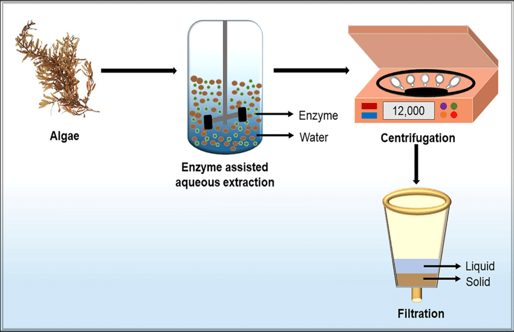

ENZYME ASSISTED EXTRACTION

- Enzyme assisted extraction represents a potential bioprocess for the production/extraction of phenolic compounds with high stability and high antioxidant activity for pharmaceutical and food applications.

- Advanced extraction technologies are needed to meet emerging requirements. The most recent method for removing bio ingredients from plant materials uses enzyme assisted extraction.

- Enzymes are categorised based on the substrates (the compounds on which they act). Some of the most common types include-

- Pro-teases (Which Break Down Proteins),

- Cellulases (Which Break Down Cellulose),

- Lipases (Which Split Fats Into Glycerol And Fatty Acids),

- Amylases (which break down starch into simple sugars) [2].

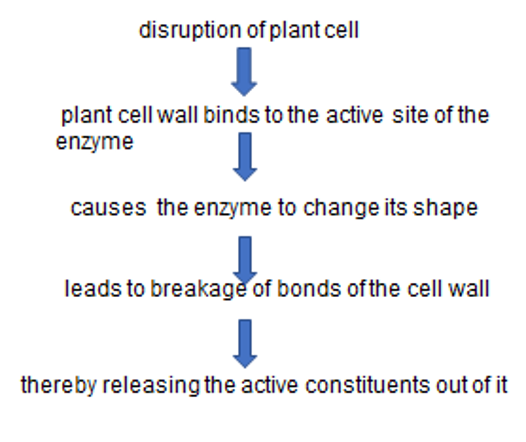

ENZYME-ASSISTED EXTRACTION PRINCIPLE

Figure 1:- Mechanism of enzyme-assisted extraction [3].

Figure 1:- Mechanism of enzyme-assisted extraction [3].

Extraction of Z-lingustilide

Enzymatic Extraction of Polyphenols From Green Yerba Mate

Ana Carolina Winkler Heemann et. al.,2019

1.The study’s objective was to evaluate the enzyme-assisted extraction of polyphenols from green yerba mate employing response surface methodology (RSM) to determine the best extraction conditions.

2.The carbohydrases use increased the extraction of polyphenols from about 38.67% to 52.08%.

3.The enzyme-assisted extraction of polyphenols from green yerba mate was considered an excellent alternative to conventional solvent extraction since enzymes are renewable matter that further contributes to sustainable practices.

Enzymatic Extraction of Polysaccharide

1.Polysaccharides are the most widely studied group of metabolites apart from polyphenols.

2.Blanco-Pascual et al. extracted carrageenan from Mastocarpus stellatus using Alcalase® (a type of protease). The extracted polysaccharides showed excellent gelling properties. The extraction process led to a simultaneous extraction of valuable phytochemicals such as polyphenols, thereby adding value to the extract.

ENZYMATIC EXTRACTION OF OIL

Conventional techniques such as hydraulic pressing, expeller pressing, and solvent extraction are used in oil extraction from seeds.

Boulila et al. extracted essential oils and phenolics from bay leaves (Laurus nobilis L.). The enzyme mixture of cellulase, hemicellulose, and xylanase proved to be helpful in improving the extraction efficiency of biomolecules from plant matrix by degrading plant cell walls.

When the substrate was pretreated with cellulase, hemicellulase, and xylanase separately and their ternary mixture, the extraction yield of essential oils increased by 243, 227, 240.54 and 248%, respectively. Further analysis revealed that enzyme-pretreated substrates enhanced antioxidant activity due to essential oils.

Enzymatic Extraction of Colours

Commercially available enzymes such as cellulase, amylase and pectinase have been explored in the past to solubilise the cell wall, leading to the extraction of pigments and flavours.

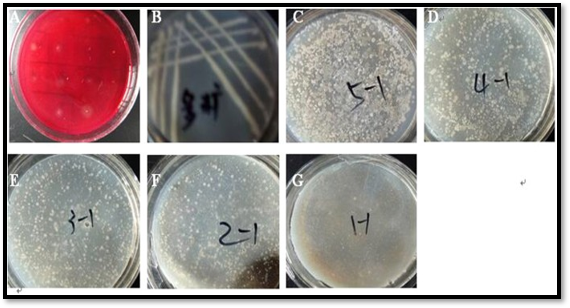

Enzyme-Assisted Extraction of Carotenoid-Rich Extract from Red Capsicum (Cpsium annuum)

Observation: Three carbohydrases enzymes, viz. viscozyme L, pectinase and cellulase, were tested for their liquefaction effects and ability to recover higher carotenoids in aqueous extract.

An incremental increase in the dosage of enzymes significantly (p < 0.05) improved the extract yield, total carotenoids, phenolics, ascorbic acid content and antioxidant activity. Viscozyme and pectinase caused significantly higher recovery of carotenoids and other bioactives than cellulase [3].

Advantages

- These green extraction methods reduce the requirement of hazardous solvents and require short extraction time.

- Faster extraction rate.

- Effortless recovery with reduced solvent.

- Additionally, as this extraction is carried out under controlled temperature conditions, it is beneficial for the extraction of thermo-sensitive molecules such as flavours, pigments and oil [2].

Critical Operational Conditions

- The temperature of the reaction,

- Time of extraction,

- The pH of the system,

- Enzyme concentration, and

- The particle size of the substrate [2].