INTRODUCTION

- The dairy industry is responsible for maintaining high hygienic standards and guaranteeing that only safe food is available to consumers. Various cleaning methods of the machinery have been incorporated to ensure the product is safe and meets food safety regulations. A proper cleaning system is necessary for a dairy processing plant. CIP in food industry stands for Cleaning In Place.

- Cleaning in Place (CIP) processes stand for automatic or partially automated internal sanitation of manufacturing facilities without requiring their disassembly. The surfaces to be treated for this sanitation procedure must be specially designed.

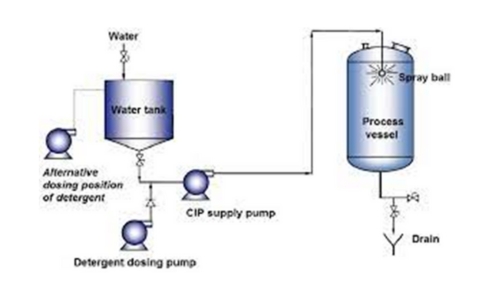

- The circular “cleaning in place” (CIP) technique has been designed to provide good results in cleaning and sanitation. The pipelines have valves that regulate the flow of fluids. CIP, or cleaning in place, is a process that automatically circulates fluid while washing and rinsing it [1].

- CIP is defined as circular washing in which fluid is circulated through tubes and machines and through the stages of enclosed machinery because it is too expensive to remove and reassemble them regularly. Therefore, the CIP process in dairy plant has become increasingly popular.

CIP Washing Systems

CIP systems can be classified as two types-

- Single cycle system – Simple closed systems (washing by circulation) are typical for small, volumetric devices like filters, chargers, or tiny CIP systems for “lost washing”. For each wash, a new cleaning solution is produced.

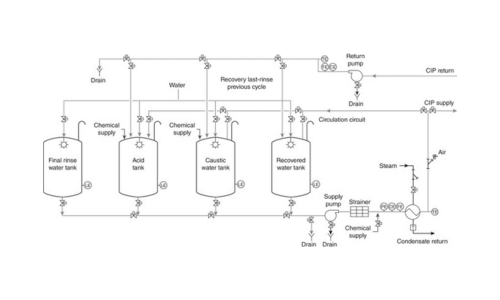

- Multiple cycle system – The automated CIP system operates the washing solution return [2].

The design of centralised CIP systems:

- Typical CIP systems have four reservoirs: one for cold water, an acid, a base, and “steamy” water. There are systems with an additional hot water tank as well. The operator can choose the washing programme.

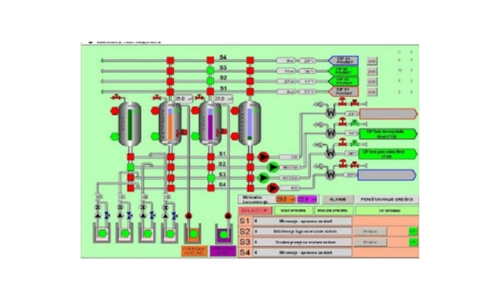

- The central computer receives all signals from the sensors and pumps. The terminal allows users to pick the washing programme cycle, create diagrams, and view all pertinent system data. The CIP system’s size and complexity can be adjusted and need not be confined.

- The equipment required to store, track, and distribute cleaning solutions to the various CIP circuits is found in a CIP station in a dairy [1].

- Many dairies have implemented centralised CIP systems; however, the distance between the central and peripheral CIP circuits is greater in large, high-processing dairies. Significant volumes of fluids are present in CIP pipe systems, even if “pumped out”. Following a flush, any remaining water in the pipes dilutes the detergent solution, indicating that substantial amounts of the concentrated detergent must be added to maintain the necessary concentration.

Figure 3: Central CIP and washing lines in dairies [1]

Cleaning Methods

According to the Dairy Practice Council, the suggested cleaning method entails [4]-

- Step 1: Prepare the solution by pre-mixing the necessary quantity of cold water with a well-balanced alkaline circulation cleaning solution to create a concentration of 0.7 to 1.0 per cent.

- Step 2: Directly pour the pre-dissolved cleanser into the surge tank.

- Step 3: Circulate this alkaline cleaning solution while keeping the temperature at 175oF for 30 to 45 minutes.

Conclusion:

- In industrialised nations, the likelihood of food-borne illnesses and the occurrence of food product defects has decreased, but not entirely disappeared, thanks to the application of modern technology to food processing techniques and microbiological food safety regulations [2].

- On the other hand, modern food production and processing methods rely on using a variety of safe technologies for cleaning and sanitising the equipment to simultaneously maintain product safety, acceptability, and consistent quality from the point of production to the point of consumption.

- The main developments in the contemporary food industry are preventing human diseases spread by food, reducing finished product failure, and improving their quality [4].

- A good and prompt application of hygienic practices is crucial in developing a healthy food product because the modern food industry has developed to include a wide range of technological processing procedures and food products.