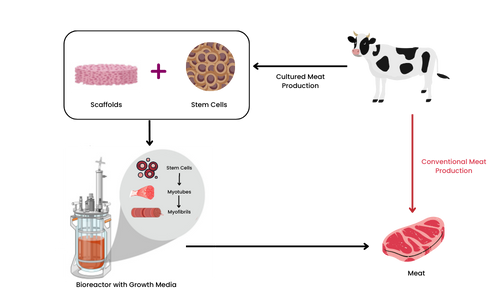

DEFINITION – CULTURE MEAT

“Cultured meat can be grown from animal cells without animal slaughter“ (Post, 2012).- Cultured beef also eliminates the need for animal slaughter and has a far lower environmental impact in terms of greenhouse gas emissions, land usage, and water consumption [1].

CELLS FOR CULTURE

- The best suitable beginning material is self-renewing cells that grow the cells needed to make meat, such as fibroblasts, endothelial cells, myofibers, adipocytes, and chondrocytes.

- Adult stem cells like satellite stem cells and Adipose-derived stem cells (ADSCs) are numerous cell sources for cultured meat applications .

PROCESS

- Satellite cells isolated from the biopsy are purified using specific cell surface markers, which upon triggering, transform myoblasts into myocytes and then into myotubes and finally into myofiber [2].

3D food printing

Layer-by-layer extruding food components create food-related 3D printing into three-dimensional things.

- The world of culinary art has printed various edible items,from cakes topizza[3].

3D food printinghas many benefits

|

|

|---|

|

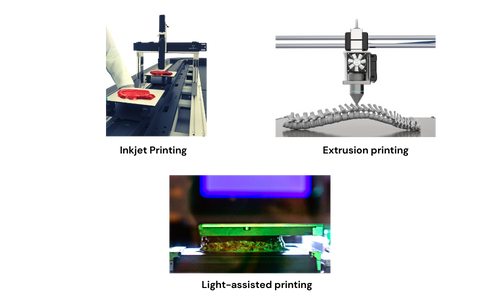

3D PRINTING OF CULTURED MEATA revolutionary method of positioning cellular and acellular elements called “bioprinting” accurately positions and distributes biomaterials with cells to create complex 3D-functioning living tissues. Three fundamental bioprinting techniques that are often employed include

|

|---|

GOAL AND MERITS

The goal of 3D printing meat is to solve major problems:

1.Reducing greenhouse gas emissions,

2.Providing consumers with a safe source of protein,

3.Encouraging a sustainable approach to satisfy meat demand

Merits of using cultured meat

- Production time

Cultured meat production takes only several weeks when compared to conventional meat.

- Risk of foodborne disease

There is a low risk of potential contamination as no handling of livestock is required.

- Land use and resource consumption

Since only a bioreactor is required to produce cultured meat, cultured meat reduces land use.

- Controlling meat composition

The composition of meat can be altered and manipulated [4].

CURRENT CHALLENGES OF 3D PRINTING IN THE CULTURED MEAT INDUSTRY

- Scaling up of cultured meat products to meet the needs ofindustrial production.

- Stem cell separation from farmed animals is challenging due o the limited scientific exploration for cell maintenance, differentiation and expansion toward large-scale capacities.

- Existing culture media and its components, such as growth and differentiation factors, are too expensive. Strategies are being proposed to bring down the cost.

- There are regulatory challenges as well.

RECENT NEWS