client

Kombucha

Our Role

We redefined fast-casual loyalty

Today’s Task

What We did Today?

Event: Fermented Tea-Based Beverage: Formulation of Kombucha with Natural Flavors

Today’s task involved developing a clean-label, fermented tea beverage, using natural fruit and botanical extracts, in the form of a kombucha prototype. Kombucha is a fermented product created using sweetened tea and the fermentation of a Symbiotic Culture of Bacteria and Yeast (SCOBY).

All kombucha has this similarity, but we chose a clean component approach, considered clean-label nutrition principles, focused on minimal processing, and used real functional ingredients. In our project, we made the formulation without artificial stabilizers, synthetic flavors, or preservatives, and natural color and flavors (with sensory appeal and microbial safety).

How I Felt Before Starting – Developing a Healthy, Natural Fermented Drink

Developing a healthy, naturally preserved fermented beverage with a unique flavor profile without compromising its sensory experience and probiotic qualities is a difficult and complex task, especially with a clean label concept, minimal processing, natural preservation, and regulatory requirements. Despite these challenges, my interest in food technology kept me focused. I actively engaged with scientific resources as well as leading food technology journals, to select the most appropriate methods for product design tailored to the client’s requirements.

🧪 What We Did Today

Our Product Development Plan – Clean Label Fermented Tea-Based Beverage

Our new product development of flavoured kombucha included two main steps:

- To develop a naturally flavoured kombucha formulation after ingredient finalization and procurement.

- To validate the fermentation and post-fermentation processing procedures to ensure product safety, shelf stability, and nutrient retention in alignment with clean-label principles.

Key Steps Followed Today:

Based on the client’s request and ingredient research, we intended to develop a variety of kombucha flavors with mixtures of fruits and botanicals. We focused on utilizing only the fruits and botanicals that provide the desired taste, visual colour, and compatibility with kombucha’s acidic fermented base.

One of the main challenges we faced was combinations that would provide some functional benefit, designed with a unique sensory profile. Also, these ingredients must not interfere with kombucha’s flavor, fermentation, or microbial balance.

To ensure safety and quality, all selected fruits and botanicals underwent standardized pre-processing and cleaning before use, including multi-step washing and food-grade hygienic protocols, per best practices for fermented beverages. This was especially important to maintain the microbiological integrity throughout the development process.

After brewing the tea leaves base, we inoculated it with a SCOBY under controlled ambient conditions to begin the fermentation process. We monitored the fermentation process closely to ensure the right balance of acidity, sugar conversion, and effervescence.

Once primary fermentation was completed, each flavor variant was infused with its botanical-fruit blend using individualized, customized processing practices. We carefully monitored and adjusted the fermentation timing, temperature, ingredient integration, and environmental control to achieve the desired sensory experience, sweetness, and overall balance for each flavored variant.

The flavored kombucha was mildly pasteurized to promote microbial stability and shelf life, while retaining the beverage’s natural sensory attributes (e.g., flavor, aroma, and color). The process was carefully optimized to satisfy the product’s clean-label requirements, minimizing the impact on probiotic integrity and functional ingredients.

The stabilized beverage was filled hygienically into pre-sterilized PET bottles and hermetically sealed to preserve the product quality. The samples are stored under controlled refrigeration for post-production quality assessments.

📚 What I Learned

- Microbial Balance and Flavor Control: I have observed that extended fermentation improved carbonation but also increases sourness. So, I have planned to monitor and adjust quality parameters closely to balance fizziness with palatability.

- Functional Ingredient Selection: I found that some flavors infused well with kombucha without compromising fermentation and acid-polyphenol interactions.

- Thermal Processing Impact: I have observed that faster cooling post-heat treatment maintained bright, volatile notes in citrus-based flavors, while slower cooling resulted in muted aroma, likely due to post-heat treatment thermal decay.

Outcome:

The flavored kombucha formulations demonstrated desirable natural acidity, distinct botanical notes, and moderate sweetness. Peach-basil and mango-ginger exceptionally achieved good balance, while other variants showed inconsistency in flavor depth and frizziness. Further refinement in fermentation time, fruit infusion ratios, and post-processing parameters needs to be considered to achieve uniformity across variants.

✅ What Went Well

- Flavor compatibility: All flavors fit well with the kombucha base, providing an appealing, balanced flavor and color.

- Thermal processing: The mild pasteurization process maintained the color, aroma, and flavor of the kombucha.

- Effervescence: The primary fermentation established natural effervescence and a balanced acid profile.

⚠️ What Could I Have Done Better

- Could have added starter tea during initial fermentation to lower pH, prevent mold growth, and enhance acidification faster.

- Needed regular monitoring for better control of fermentation time and environmental conditions.

What made to choose FRL

We help you to comply with guidelines and attain certifications that you need.

What made

Choose

FRL

Caramel

Thank you for the Update and effortd caramel. We Appreciate the detailed trials and variations you've conducted. Please Ensure the flavor alignment is testes accordingly. I look forward to the final version and appreciate your continued dedication.

Project Code:24FRL-BEV-NPD 4577-01

Name:Mohammad Hassan

Pasta

Very First thing, You all should feel proud yourself that you made something that do not exist in market. Heat and eat pasta with bold flavours.

Project Code:24-FRL-FOD-NPD-2462-02

Name:Miral

Protein Biscuits

V19 plain is the best anf finalized from our side. It is accurate in taste(plain), texture, and after tastte is also not bitter at all, He loved it as a plain flavour. V19 cardomon should add more flavour rest everything is fine.

Project Code: 24-FRL-FOD-NPD-3449-01

Name: Mehul Molir

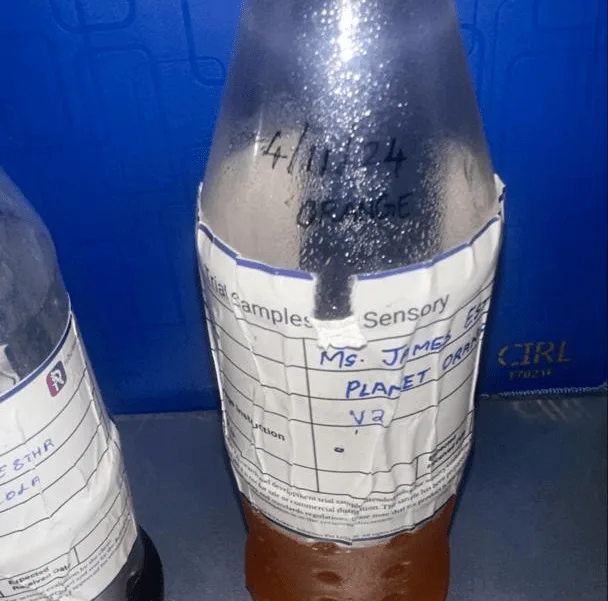

Cola

Hello, I am using the oppurtunity to appreciate the teams effort we will be picking V1 for cola, So far we don't have any complain about it, I will like to know the type of sweetner use, during the taste test some said it too sweet while some said it for orange we are picking V2, no complain too, thank you once again

Project Code: 24-FRL-BEV-REV-2878-01

Name: Esther

Energy Candy

Since a year Ago, we statrted this journey of developing energy candy and we took different steps to develop the product. I am really happy to see endless efforts you people have done to develop an energy candy, Hats off to you and your didication towards unbiased work

Project Code: 24-FRL-NPD-FTP-PMR-2660-02

Name: Harshad

Let’s create something Innovative and Delicious together

Food Research Lab strives for excellence in new Food, Beverage and Nutraceutical Product Research and Development by offering cutting edge scientific analysis and expertise.