Extruders can be thought of as high temperature short time cooking (HTST) equipment, that can transform various raw ingredients by forcing through a die to create the desired final product shape during new product development in the food development companies. A food extruder accelerates the restructuring process for food ingredients, compared to other traditional food processing methods. Extruders are highly multi purposed as they can be used to cook, form, mix, and texturize food products with added flavour, quality retention and increased productivity at a low-cost.

How to choose your Next Extruder?

Extruders can be thought of as high temperature short time cooking (HTST) equipment, that can transform various raw ingredients by forcing through a die to create the desired final product shape during new product development in the food development companies. A food extruder accelerates the restructuring process for food ingredients, compared to other traditional food processing methods. Extruders are highly multi purposed as they can be used to cook, form, mix, and texturize food products with added flavour, quality retention and increased productivity at a low-cost.

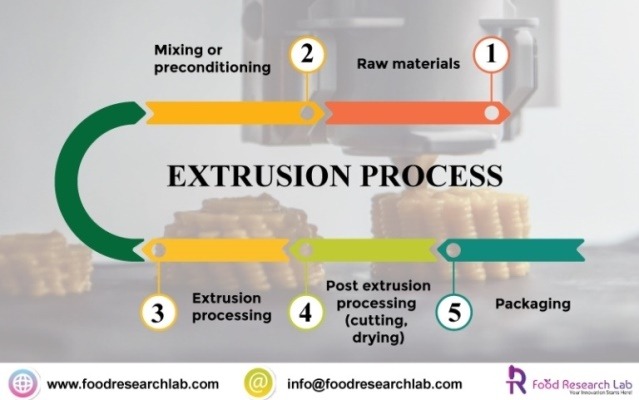

Process in brief

During the extrusion process [u1] , raw materials are ground to the preferred size, which then passes through a preconditioner. At this stage, steam may be injected into the raw materials and finally reaches the die assembly at a defined throughput. Extruder feeds both solid and liquid ingredients, mostly grain pulse, root-based foods, water, oil, sweeteners, colours, and added vitamins and minerals.

Extrusion is a process used to create objects of a fixed cross-sectional profile. A material is pushed through a die of the desired cross-section. The extrusion process can be done with the material hot or cold.

Extruder’s design and specification can be tailored for the ideal and intended manufacturing application of food products. There is a complex interaction between feed ingredients, extruder design and operating conditions, affecting product development, quality improvement, consistency, and optimum operation efficiency (1).

Extruders can generally be classified based on the build type, such as single screw extruder, twin screw extruder, parallel twin screw extruder, pelletizing Extruder and dry Extruder. The following variables affect the efficiency of the extrusion process. Firstly, raw material’s physical and chemical properties, such as viscosity, moisture content etc. The dough’s rheological behaviour can greatly influence the final product quality, process time, and heat transfer. Secondly, thermomechanical cooking factors[u2] , such as the design of the equipment including the type of screw, variable screw diameters (D) and lengths (L) and barrel section of the machine, die design and opening shape and section (2).

The die plate assembly design is a crucial part of the operation as it is responsible for forming the desired product shape and adds flow resistance to achieve a final output of transformed materials. Bronze dies produce better quality pasta compared to stainless steel dies. Finally, operating conditions of the equipment such as screw speed, temperature and overall water content contribute to the process’s efficiency.

For instance, during the extrusion process, caution must be given to the heat generated from screw elements, the heating system and the self-heat gained by the barrel’s viscosity. Water is greatly used in combination with the extrusion process to characterize the melting behaviour and overall final dough rheology. Moreover, it is also used in the form of steam to impact the total extruder energy output. Such usage can significantly impact the extruder selection, design and performance and mainly on the product quality. The remaining water is evaporated during the venting stage to achieve accelerated cooling to form the final product (3).

There are different categories of extruders, such as cold, hot, steam-induced and co-extrusion. Cold extrusion is mainly used for gentle mixing and shapes the dough without heating or cooking, such as pasta. Hot extrusion converts the raw materials under high temperature and pressure in a short time. This type is considered for textured foods such as pet food. Steam-induced extrusion is used for determining the textural attributes of highly expanded products, such as expanded breakfast cereals. Co-extrusion can be very helpful for products with dual textures, such as crispy shell and soft filling. Co-extrusion combines stem induced expansion as well as injection filling.

Global leaders

There are several types of extruders available in the market, confusion for food manufacturers, based on the product type. Some manufacturers who supply single-screw extruders are American Extrusion International, Wenger, Extru-Tech, and Schaaf Technologie. Companies such as Buhler, Baker Perkins, Clextral and Coperion offer twin-screw extruders.

Brabender CW offers extruders at a pilot scale level. Extruder KE 19 is a single screw extruder with a screw diameter of 19mm and has an output of 5kg/hr. Single screw extruders are open channel extruders, which can be thought of as a drag flow pump, with the final output delivery controlled by the pressure flow.

Syringe Extruder

Screw Extruder

Filament-Fed Extruder

This Extruder comes in handy for product development, specifically to test the extrusion properties of different raw materials and develop the processing characteristics. Process stimulation could be done with ease under low R&D costs. Stimulations such as cold forming, shaping, gelatinization, plasticization and expansion. This Extruder also aids in increasing the time efficiency to characterize the sensory and rheological characteristics.

Brabender CW also offer a twin screw variety, TwinLab-F 20/40. Twin screw extruders contain two screw as the name suggests which counter-rotate forming closed channels. The output from this type of Extruder is less vulnerable to pressure flow and can be considered as a positive displacement pump (2). The TwinLab-F20/40 model has been designed for lab scale applications at different L/D ratios. New product developments in snack, breakfast cereals, sweets, and pet food category can be prepared on a lab scale. It contains either a 600 or 1200 rpm motor and horizontally divided barrel that can be opened to observe and clean. It also contains 4 different heating zones and water cooling.

Alternatively, Buhler group offer twin screw extruders. ECOtwin variety is specifically tailored for the pet and sea food industry. It offers a screw diameter of 5 to 7 inches and produces 20,000kg/hr. Whereas the POLYtwin option is a parallel twin screw extruder. Its screw diameter ranges from 2 to 7 inches and offers up to 450 kg/hr. Due to its modular design, it is highly flexible. It can be used for food ingredients, breakfast cereals, sea food and pet food. POLYtwin also offers a robust and fully automated screw ejection unit, thus reducing the risk of damaging the elements. Knife heads can be changed easily without disrupting the production process. Flexible cutter for a consistently high quality end product is yet another advantage.

Let’s create something Innovative and Delicious together

Food Research Lab strives for excellence in new Food, Beverage and Nutraceutical Product Research and Development by offering cutting edge scientific analysis and expertise.