There are dietary concerns among consumers to choose a healthier lifestyle and follow food trends to prevent nutritional deficiency and long term prevention of chronic diseases. Consuming processed fast foods in large is leading to different extremities, such as lack of nutrition and aggravation of chronic diseases such as obesity and hypertension. Thus food scientists and manufacturers are focusing on novel and sustainable ways for selecting suitable processing methods to create healthy and convenient foods. Extrusion processing can serve this purpose.

Innovations in extrusion cooking for Food Product Development

There are dietary concerns among consumers to choose a healthier lifestyle and follow food trends to prevent nutritional deficiency and long term prevention of chronic diseases. Consuming processed fast foods in large is leading to different extremities, such as lack of nutrition and aggravation of chronic diseases such as obesity and hypertension. Thus food scientists and manufacturers are focusing on novel and sustainable ways for selecting suitable processing methods to create healthy and convenient foods. Extrusion processing can serve this purpose.

As explained in our previous blog, extrusion cooking uses a blend of high temperature, pressure and shear conditions which results in biochemical changes in the food materials. This leads to inactivation of microorganisms, denaturation of proteins and enzymes, lipid modifications, gelatinization of starch, the formation of volatile compounds and increased availability of soluble fibers (1). Moreover, the extrusion process has the ability to retain the bioactive compounds and provides a platform to enrich the ingredients with protein, fibre, antioxidants, vitamins and minerals. The impact of extrusion on the levels of bioactive compounds was evaluated. Factors such as food structure, shear, resonance time, temperature and moisture content contribute to the overall composition and potential release of functional bioactive compounds (2).

Extrusion based 3-D printing

3-D printed extrusion is a digitally controlled extrusion process, and currently being utilized to build products with complicated design, geometry, food structure with high surface to volume ration and compositions etc during new food product development. Food products such as chocolates, processed cheese, chocolates and sugar cookies have been manufactured using 3D printing. The robotic construction used computer loading of food materials and extruding on a layer by layer deposition. 3D printing technology is gaining attention for older adults with mastication and swallowing difficulties. Moreover, 3D printed meals can be served to people with dysphagia.

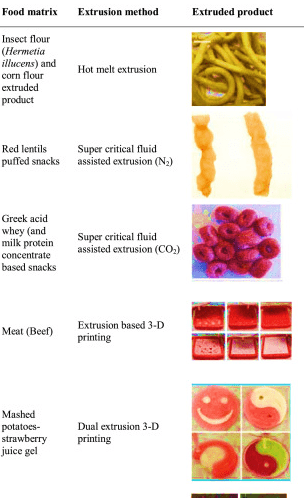

Table 1 NPD using 3D printing extrusion technology. Table adapted from (3).

| Food Matrix | Product Composition |

| Egg rice | Egg white, yolk and rice flour |

| Egg yolk | Heat-induced egg yolk paste |

| Soy protein concentrate | Soy protein isolate with xanthan gum |

| Potato and probiotics | Mashed potato and Bifidobacteriumanimalis subspp.Lactis |

| Beef and lard | Beef and lard |

| Cereal snacks with insects | Wheat flour dough and yellow mealworms |

| Chocolate button | Dark chocolate, magnesium stearate |

| Turkey meat and celery | Transglutaminase, turkey meat puree and celery |

There are a few critical parameters that need to be controlled during 3D printing extrusion to achieve a product with excellent mechanical integrity and stability. The temperature of the extrusion, printing time and speed, rheological properties of the food inks. Products do not expand if the temperate is below 100°C. Expansion rate increases with an increase in temperature, with moisture levels close to 20%. At lower extrusion temperatures, starch is completely molten and thus expansion is reduced. On contrary, the gel formation is elastic at higher temperatures with smaller uniform cells. An increase in temperature should reduce the overall viscosity of the material by favoring bubble growth and resulting in low density extrudes. Finally, post-processing of 3D printed foods after deposition is essential to enhance the sensory appeal and palatability.

Novel Meat analogues

In India, vegetables, pulses and cereals are readily available to be used as ingredients in meat analogues. Not only from India, vegetables grown in other countries such as Saudi Arabia the UK. The nutritional and functional characteristics can be improved. The final product composition can be altered by physical losses, such as evaporation of water, leakage of oil and volatile compounds. The common physiochemical changes which occur during extrusion are binding, loss of native conformation, thermal degradation and fragment recombination. Improved Extrusion cooking technology (IECT) is a novel method modified from a single screw extruder for developing textured rice.

The texturization process by extrusion can be used to replicate the texture, taste and appearance of meat in plant-based foods. Dry extrusion can be applied to produce meat extenders and wet extrusion for meat analogues (2). The disulfide bonds in protein break and reform during the extrusion process. Enzymes also lose their activity during extrusion due to high temperatures and shear. The main application of extrusion with protein foods is texturization. During the extrusion process, starch degradation results in reduction during expansion. The amylose and amylopectin content are hydrolyzed to maltodextrins. This implies in highly expanded products may crumble while dense products are too hard. Starch gelatinization occurs at much lower moisture contents (12-20%) in comparison to conventional methods.

Lipid content above 5% in foods is considerable for the reduction in the expansion rate. The type of starch lipid complex present in the raw material influences the formation of the amylose-lipid complex being more favorable than a triglyceride.

The fibrous texture development is the challenging part of the extrusion process. Fibers form a viscous network to determine the physiochemical conditions. Soluble fibres are able to modify the pH and microflora of the colon leading to the modification of mutagenic agents.

Table 2 List of meat analogue and fortified extruded products. Table adapted from (3).

| Food Matrix | Product Composition |

| Soy protein concentrate (SPC) and micro algae | Spray died micro algae and SPC |

| SPC and wheat gluten | SPC at 40% and wheat gluten (0-40%) |

| Renneted casein gel | Milk, calcium chloride, lactic acid and chymosin |

| Gluten-free probiotic, lentil flour and yeast | Lentil flour, Saccharomyces cerevisiae (Nutritional yeast extract) |

| Semolina extruded with mushroom | Semolina, white button mushrooms, shitake and porcini mushrooms |

| Cheese flavored snacks | Corn grit, salt, sunflower oil, monosodium glutamate, amino acid cysteine and butyric acid. |

| Red lentil puffed snacks | Red lentil flour |

| High fiber RTE expanded snack | Barley flour, carrot pomace |

| Expanded snacks from pea and oats | Pea starch and pea protein oat fiber |

| Insect based meat analogue | SPC, soy fiber, Alphitobiusdiaperinus protein concentrate |

It can be currently defended that extrusion technology allows large scale production for food product structuring. Moreover, promising value addition in the foods such as added proteins, fibers and other nutritional components are essential for biochemical and physiological processes.

Let’s create something Innovative and Delicious together

Food Research Lab strives for excellence in new Food, Beverage and Nutraceutical Product Research and Development by offering cutting edge scientific analysis and expertise.