Ultra-High Temperature In Beverage Processing UHT

Ultra-High Temperature is the abbreviation for Ultra High Temperature. This is the sterilizing method most commonly used for items with a high ph, such as milk, soya, and other dairy products.

UHT Systems with Indirect Heat Transfer

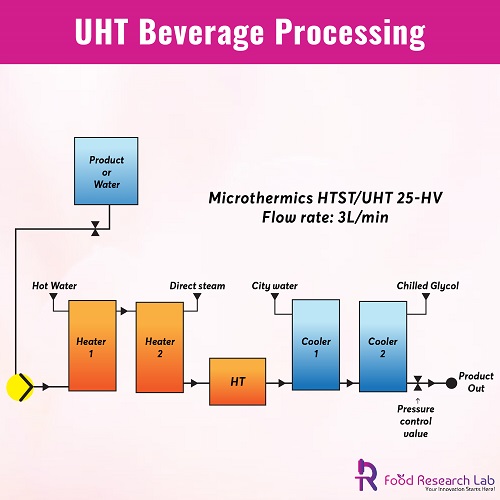

The heating source and the product are not directly contact with indirect heating systems but are separated by equipment contact surfaces. Tubular heat exchangers or corrugated pipes are used in UHT systems. In a short period, they may achieve temperatures of up to 145oC, and the product will only be exposed to these temperatures for 3-4 seconds before being cooled to temperatures below 30oC.

Heating systems that use direct heat

Direct contact with a steam of potable or culinary quality heats the product. Direct heating has the advantage of keeping the product at a higher temperature for a shorter amount of time, which implies less harm to a heat-sensitive commodity like milk.

Injection direct heating systems use a steam injector to inject high-pressure steam into a pre-heated liquid, resulting in a fast temperature rise of 80 to 145 oC for 0.5 seconds. Following that, the product is flash-cooled in a vacuum to remove water equal to the quantity of condensed steam consumed until it reaches 80 degrees Celsius. A heat exchanger then continues to lower the Temperature.

The beverage business has seen its fair share of technical improvements throughout the years. Food & Beverage Technology Review has detailed some of its most interesting ideas to follow beverage sector tech developments, such as industrial automation and blockchain. Of all, this is only a piece of what the market has evolved into.