Supplement Coatings

The film coating of tablets or capsules is an important step in the process of manufacturing a dietary supplement, which originated in the pharmaceutical manufacturing process. The reasons for coating can be quite diverse. First, there may be technical reasons to make the product easier to swallow, for example, or to improve how it feels in the mouth, or to conceal taste and aroma.

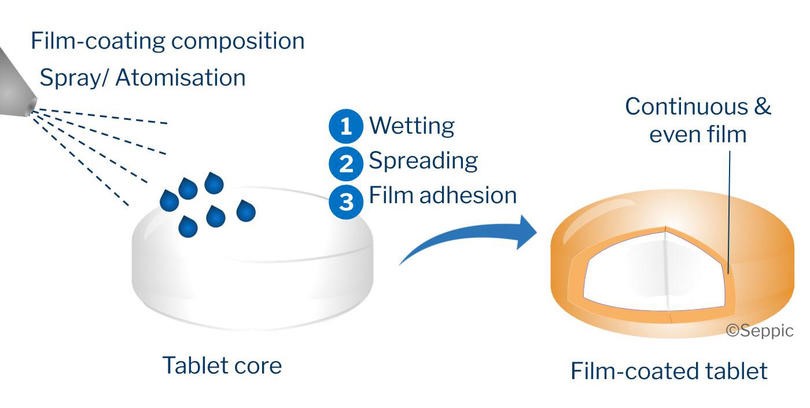

Fig.1. Supplement Coatings (Seppic.com)

Another reason for film coating is to make the product more stable especially if the product contains active ingredients, which are sensitive to humidity, oxygen, or light. This is to prevent chemical reactions of the active ingredients, which could affect the properties of these ingredients. Delayed release by enteric-coated film coating is another possibility. Coloured coating helps a user to distinguish various products or dosages, but quite often it is also applied for appearance. This can promote a positive feeling and recognition value for a medication or dietary supplement by brand recognition. Film coated tablets are also more resistant to mechanical influences than the uncoated tablets. The end consumer recognises the product as a premium product, associating it with consistent high quality. Another advantage is a certain protection against product counterfeiting by the additional film coating, since complex coating technology requires extensive technical know-how. For soft gel capsules, an enteric coating can eliminate the ‘burping’ problem, which can be a side effect for people with sensitive stomach. These are all ways to promote long-term loyalty in the end consumer.