Plant Protein isolates and concentrates for Vegan meat Formulation and Production

Consumers are well conscious of the overexploitation of natural resources and the environmental issues associated with it. Plant-based products are developed as a potential replacement for meat, and seafood-based products offer great potential for preventing premature deaths and limiting Green House Gas Emissions. Markets and Markets approximate that by 2025, the plant-based meat market’s value will reach a value of US$27.9 billion from US$12.1 billion in 2020. The nutritional sense was explored historically with products such as seitan, tempeh, tofu and soy. The current research and development focus on developing and producing a sustainable method of recreating conventional meat that tastes like real meat. We can see products such as chunks, patties, burgers and sausages made from plant-based sources. At this stage, processing technologies such as extrusion cooking, freeze alignment, spinning and shear cell technologies are used to develop these products. These technologies are used to texturize the protein from oilseeds, grains, and pulses forming various structures. Quorn has been using fermentation techniques to grow mycoproteins to produce alternative meat. Typical plant-based beef is made from texturized or non-texturized proteins with a bottom-up approach where individual fibres are assembled to flesh like structures. On the other hand, a top-down approach could be utilized where the dough is formed into structured meat-like products using extrusion technology.

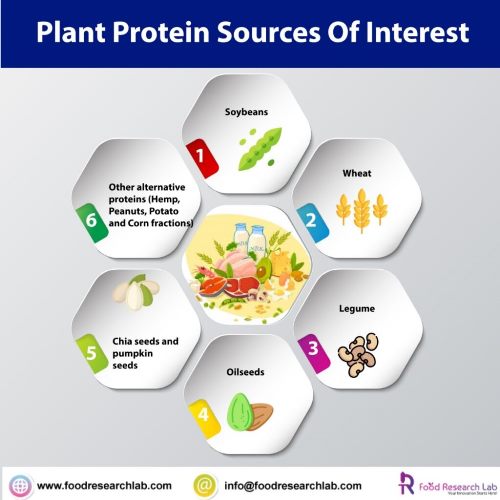

Plant protein sources of interest:

Table 1. Sources of plant proteins and their use in meat analogue preparation. (Adapted from Asgar et al.

| Plant source | Protein types | |

| Wheat | Gluten (Gliadins, and Glutenins) | Impossible burger |

| Filamentous fungus (Fusarium venenatum) | Mycoprotein | Quorn |

| Legumes | Legumin and Vicilin | Meatless uses lupine, and several other brands use the legume soybean |

| Oilseeds | Albumins, Globulins, and Glutelins | Products made from the seed cake of oilseeds such as hemp and flax |

| Rice | Glutenin, globulin, albumin, prolamin | Bahama Rice Burger that uses Risofu |

| Pea (Pisum sativum var macrocarpon) | Pisumin, Legumin, vicilin, albumins | Burgers and other analogues made by Beyond meat Inc. |

Soybeans are made up of insoluble and water-soluble proteins, which can be extracted and stored as globulin and whey fractions via acidification at a pH 4.5–4.8. The final protein content and other compounds such as carbohydrates will dictate the functional properties of soybeans. It was found that the proteins with higher 7S fractions developed gels with higher stress and water holding capacity at pH 3.Presence of soya saponin dictated the interactions of proteins, foamability and surface elastic properties. Carbohydrates such as inulin improved the hardness, such as in tofu, and the incorporation was enhanced to form a gel matrix. Soy protein concentrates and isolates powder is used to manufacture muscle meat analogues such as sausages and burgers. The production protocol dictates the ingredients and their functionality. Defatted soy flour with a protein content of at least 50%and soy milk has been used to manufacture protein-rich products. Soy protein isolates have protein content in the range of 70% to 90% depending on the extraction methodology. For the application of vegan meat, the protein content need not be high. Soy isolates or concentrates with at least 45 % protein composition can be used for good solubility, gelling emulsification, improved water holding capacity, fat retention and enhanced texturizing properties.

Wheat is a much cheaper alternative when compared to its competitors. Wheat gluten is used as a structuring agent as well as a binder. For instance, wheat gluten is responsible for dough forming capacity, binding, viscosity, swelling and nutritional quality. The shear cell can change the wheat into fibrous structures during extrusion to mimic the whole cut to minced meat appearance. Gluten makes thin protein film upon deformation and elongating the analogue dough into a fibrous material. The functionality of gluten is based on glutenins and gliadins.

Figure 1. Home-made seitan. Source: prepared by Manijeh Mistry (principal author)

Legume proteins such as those obtained from lentils, mung, pea, and faba bean and their functionalities have been evaluated. Pea protein has gained attention in the market for its emulsification, gel formation, and stabilization of the estimated proteins. The composition and ability of pea ingredients are used to generate a firm texture, water binding, and fat reduction. High moisture extrusion and shearing were used to produce meat analogue fibres. Hydrocolloids are often added to the pea protein-containing meat analogues recipes.

In contrast, faba bean, chickpea, mung bean and lupin proteins have been found to have suitable emulsion, gelling and foam stabilization properties, making them an alternative to forming sausage type meat. However, proteins from lentils and faba beans were found to have weaker gelling capacities.

Oilseeds based proteins such as rapeseed, canola, and sunflower based isolated and concentrates gained much interest. Research suggests that sunflower protein concentrates have mild water holding capacity and contains good stability for emulsions and foaming. The protein isolates are kept at pH 4-5, near the isoelectric point while applying heat. Sunflower protein concentrates exhibited enhanced gelation capacity. Quinoa isolates have showcased a solubility of 50% at a neutral pH, with emulsification, gelation and foaming properties similar to that of soy protein.

Chia seeds and pumpkin seeds are also gaining significant attention in the market. Researchers are focusing on the isolation methods and the resulting functional properties. Initial results indicate they could be used in emulsion types of meat analogue products, such as sausages and patties.

Other alternative proteins, such as hemp, potato, peanuts, and corn fractions, are also used in food applications. Peanut flour has been used as a texturized protein using a single-screw extruder to obtain the desired functionality compared to soy flour. As a potential alternative, peanut protein concentrates displayed enhanced oil binding and foaming properties in soy protein isolates. Peanut protein isolates are also proven to have higher viscosity and more robust gel formation capabilities upon heating. Meat analogues, such as ground meat, were made from defatted peanut flour with 55% protein content. The functional, physicochemical and sensory properties were similar to that of soy texturized vegetable protein.

Protein extracted from hemp seeds were found to exhibit a wide range of functionalities and applications, such as emulsification, oil and water binding activity, and their solubility. These properties are dictated based on the extraction and isolation procedures. The gelation concentration of hemp protein is between 12 % to 22% w/w. Potato proteins contain patatin, which has a shallow denaturation temperature of 55°C to 75°C and can make a good texturizer with gelling, emulsification and foaming properties.

Based on this overview, we can understand many sources are studied, but some promising proteins are not yet commercially feasible. The complexity of the fractionation process hinders the economic feasibility.

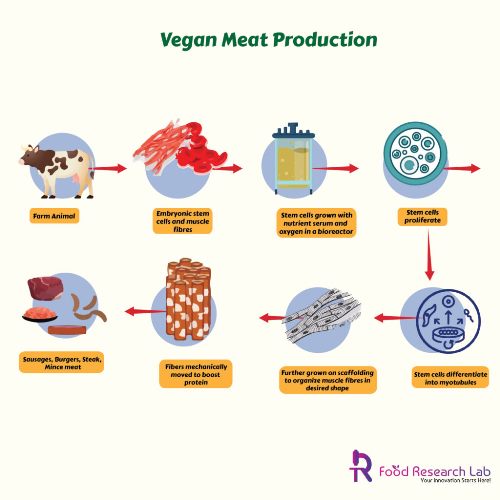

Lab-based meat production

Food Research Lab can help you solve these problems related to the formulation of vegan meat. FRL is for food and nutraceutical manufacturers as well as those companies involved in NPD and developing spec without manufacturing. FRL gives you the ability to improve all phases and aspects of new product development, such as original specification, ideation, shelf-life, packaging. Additionally, you can get them out to market quicker than ever before.